RECOTUG pushes towage operations into the future

The development of the world’s first remotely controlled tug will transform towage operations in ports, and provide new and safer roles for seafarers in the future.

-

Text:Marketing & Communication Department

Photo:©Svitzer

-

Gunvor Hatling MidtbøVice President, Communications

Kongsberg Maritime is leading the way in the automation of the maritime sector with a pioneering project to develop the world’s first remotely controlled tug.

The RECOTUG™ initiative, in collaboration with Svitzer, the global leader in towage operations, and the American Bureau of Shipping (ABS), will be piloted in the Port of Copenhagen, Denmark, by the end of 2022.

KONGSBERG’s expertise in remote-control systems, autonomous technology and system integration will complement Svitzer’s vast experience of towage operations, including its freshly developed remote tow line handling and automated mooring systems.

ABS will deliver the guidance and knowledge necessary to gain regulatory authorisation for this world-leading technology.

The RECOTUG™ endeavour expands on a remote control trial conducted by Kongsberg Maritime and Svitzer in Copenhagen in 2017, which proved the concept of a remotely operating tug from a shore-based control centre.

KONGSBERG’s technology has developed to such an extent that the project is a significant step change in capability and ambition compared to the original pilot.

Carl Johansson, KONGSBERG’s Manager for Control Applications, explains: “While the 2017 demonstrator project proved the concept, the technology we have at our disposal today means that RECOTUG™ is no longer a simple demonstrator project – its aim is to provide Svitzer with a commercially viable product that the company will be able to use in its operations worldwide.”

Thomas Bangslund, Group Head of Innovation at Svitzer, adds: “The original scope of the pilot was to assess if the remote control technology would allow us export situational awareness to an off-vessel location, and in a way that the captain was comfortable operating the vessel. This proved the case and now we are challenging ourselves to develop a tug that we can operate safely and efficiently from shore, down the line, potentially without a crew on board, so it’s a completely different ballgame.”

The RECOTUG™ concept will be developed on a new build 25-metre 2 X 2000 KW-powered harbour tug, which will be delivered in the fourth quarter of 2022. Thereafter, it will be fitted with KONGSBERG’s K-Chief 700 marine automation monitoring and control system and its SeaAware system, which combines radar and electro-optical sensors, together with attitude, positioning and AIS sensor data to provide unrivalled situational awareness for the shore-based operator..

While the new tug has been designed to include the customary facilities to accommodate a crew, once the KONGSBERG systems have been fully tested, the tug has the operational potential to be deployed as a remotely controlled unmanned vessel.

Svitzer is also introducing technology to enhance the tug’s ability to work remotely through its self-mooring system and the remote line handling system, which is currently being developed in sea trials.

One of the most perilous elements of a towage operation is when the tug has to engage with the much larger connecting ship and the tug crew have to physically ‘catch’ the ship’s weighted heaving line from the deck – particularly dangerous in bad weather conditions. Once the heaving line is captured, a crew member attaches the tug’s towing line to it so it can be winched aboard the connecting ship and secured for towage. In order to improve the safety of this operation, Svitzer has developed a line catcher ‘arm’ at the bow of the tug which gives the connecting ship a 6-7 metre ‘target’ to hit with their heaving line and which can then be secured automatically without the need to expose crew during the process.

“RECOTUG™ has the potential to change our business and increase the efficiency of our operations, but it's important to stress that RECOTUG™ is just one vessel right now, so we have a long journey ahead of us.”Anders Thybo, Program Lead Operational Innovation, Svitzer

People skills remain essential

Despite the advanced technology being deployed in the RECOTUG™ project, at the heart of the system will be a human operator in the form of an experienced tug captain and supporting marine engineers. These skills and experience are essential as towage operations are extremely complex procedures, particularly as there are so many local variables such as wind, currents, other port traffic and the relative power of the tug to the connecting ship.

Carl says: “It is essential that, from a technical and safety standpoint, we take the remote control route rather than a fully autonomous system so we have a skilled captain guiding the operations from the safety of a shore-based centre.

“One of the key learnings from the 2017 pilot was the importance of the user experience, particularly regarding technical issues like potential video image delays and its effect on the control of the tug. We learned a lot about what response times were required to operate effectively by remote control and the adaptability of the captains surprised us too: we thought they might need a few weeks to get used to the video control room and the remote operation system but they picked it up within a day.”

Although the technology is being developed on one tug, the system will ultimately be flexible enough to be installed on all types of towage vessels to provide a universal system for Svitzer’s fleet of tugs across the world.

Rewriting the rules

Another challenge for the RECOTUG™ is how a remote controlled vessel can meet current marine regulations and this is why ABS has come on board to assist the project in these, as yet, uncharted waters.

Thomas adds: “To start from scratch and rewrite the rules for a potentially unmanned tug would take too long and by the time this was agreed the technology would have moved on considerably, so we are basing our body of evidence and safety arguments from the RECOTUG™ trials around equivalence with existing rules. ABS has made some progress with this approach and we are hopeful that their guidance and expertise will show that we can operate remotely and safely within the existing regulations.”

Thomas Bangslund, Group Head of Innovation at Svitzer

“RECOTUG™ offers an opportunity to demonstrate the practical example of remote-control operations,” says Gareth Burton, Vice President, Technology, ABS.

“The application of autonomous and remote-control options to support marine operations is of increasing interest in the industry. Through projects such as RECOTUG™ we are able to ensure development of a rules and guidance framework that keeps pace with practical applications needed by the industry,” Gareth adds.

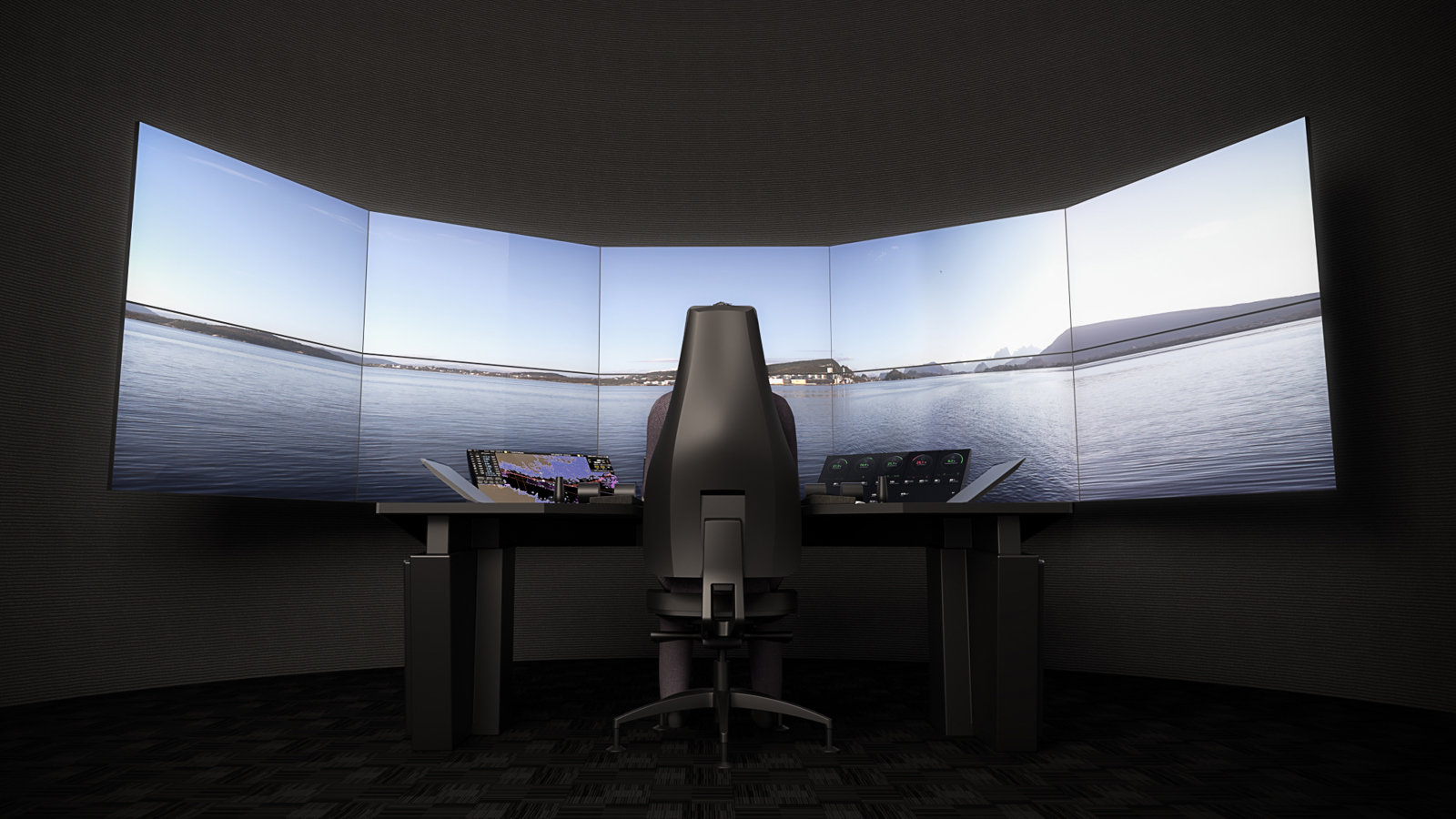

RECOTUG™ new design of the remote control center

Carl continues: “There are many advantages of working by remote control and a big benefit is the safety angle. Towage operations are high risk enterprises and, although accidents are rare, the snapping of a towline can have serious repercussions for the crew on deck; with a remote operating vessel this risk is removed completely as there is no one in harm’s way. But people are still at the heart of the operation; we still need the same skill sets as we have today but they will be deployed in more optimised settings and away from danger.”

Inclusive career prospects

Carl believes the future deployment of remotely operated tugs will also be beneficial for the maritime sector, which is currently failing to attract enough young people into the industry, and will help to make it more inclusive. Providing a shore-based ‘office’ environment using advanced technology will be more appealing to young people considering a career in the industry.

With the continued growth in maritime trade, with larger ships wanting to spend the minimum amount of time in port before setting off to their next destination, there is pressure on towage operators to match the needs of the industry, as Thomas explains: “Technology, global trade patterns and renewable energy demands are influencing our customer’s demand for towage and we need to be able to adapt to shifting needs.

“There's a general data drive from customers to know exactly what service they have been receiving, including sustainability issues around documenting emissions etc., so there's a big move towards digital-enabled assets in general. The technology we are developing with RECOTUG™ will enable that digital capability and help optimise our ability to ensure the timely and efficient entry and exit from ports to help shipping operators conserve fuel and save time.”

“It is essential that, from a technical and safety standpoint, that we take the remote control route rather than a fully autonomous system so we have a skilled captain guiding the operations from the safety of a shore-based centre.”Carl Johansson, Manager for Control Applications, Kongsberg

“It will take time to ensure the mandatory safety case and obtain approval from flag states, and any eventual implementation is a process that would be undertaken with due consideration and care. If implementation was decided, then any changes to crewing models would be introduced gradually over time, in close collaboration with regulators, unions and relevant industry bodies to ensure a collaborative approach which minimises impact to employees.

“However, it’s important that we embark on this project now as advanced autonomy is being developed across many different industries today, and it will play an increasingly larger role in the maritime industry in the future. We are determined to be at the forefront of the innovation in this space as it’s something our customers expect of us as they look for better and more efficient services.

Carl concludes: “Svitzer has been a really good partner to work with as they have so much knowledge and information that they are willing to share with us to help progress the RECOTUG™ project. Although KONGSBERG has proven capabilities in autonomous technology we are deliberating choosing the remote control approach for this project as the involvement of skilled tug captains and engineers brings so much value to the project. So we look at the RECOTUG™ project as providing the perfect balance between innovation, technical challenge, human experience and customer benefits.”

The overall objective of the project is to deliver a remote-controlled tug, enabling a full towage operation to be performed from a remote bridge located in a shore-based operations centre. This will entail:

- Unmooring the tug

- Mobilising tug to assisted vessel

- Connecting to assisted vessel

- Performing towage job

- Returning to berth

- Mooring