The world’s population is expected to grow by 2.3 billion people by 2050. This means that food production should increase by nearly 70%. How? Offshore fish farming might offer one solution.

-

Text:CHRISTINA FJELLSTAD

-

Ove Ronny HaraldsenGroup Communication Manager

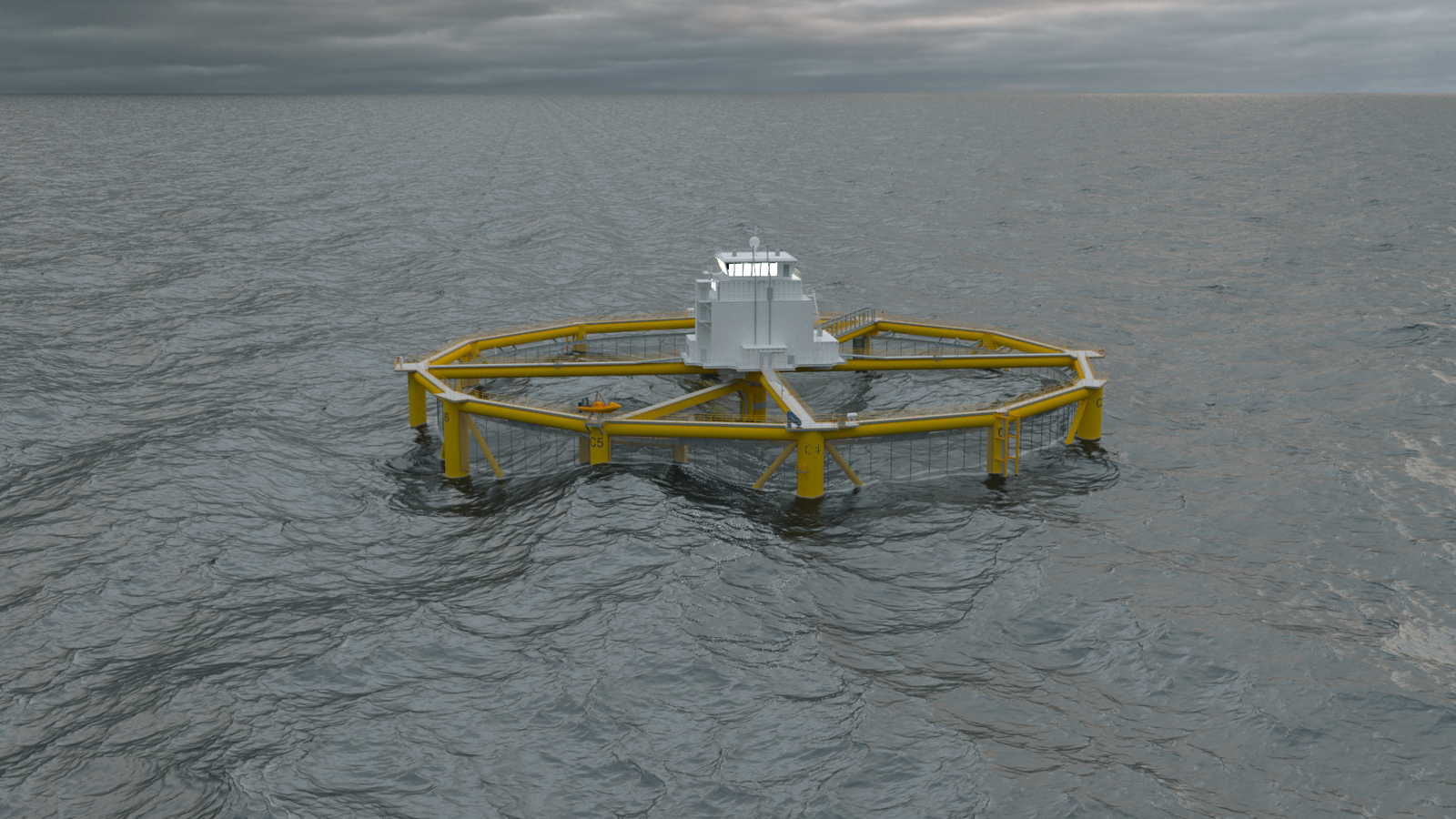

Imagine a fish farming facility large enough to fit the entire Goliat platform inside, with the capacity to breed 1,5 million fish a year placed far away from land in a harsh offshore environment. Would you think it was science fiction? This scenario is close to realisation. While a full scale pilot has already been planned and is awaiting decision for construction, this might become a real production facility from 2017.

“Fish is one of the last living creatures we still hunt in large quantities in the wild. We have to change the way we think about fishing and make use of new ocean territories in order to meet the future demand for nutrients for a growing world population. As stated by the Food and Agricultural Organization of the United Nations, the production of sea food has to increase, primarily through aquaculture,” comments Gunnar Myrebøe, COB in Ocean Farming AS.

Gunnar Myrebøe, COB in Ocean Farming AS.

AN ENORMOUS RESEARCH FACILITY

After a lifetime of experience from Norwegian oil company Statoil, Myrebøe was headhunted to manage this specific project for Ocean Farming, a subsidiary of SalMar ASA. The project started 3 years ago and was initiated by Gustav Witzøe, the founder and main owner of SalMar, as a response to the increasing need for fish protein and nutrition. His idea has resulted in plans for a full scale pilot combining technology from the fishery, fish farming and offshore industries.

“The pilot will function like an enormous research facility where we collect data to be used in the further development of offshore fish farms. During the first period, our main focus is to ensure the facility functions properly, to ensure that it is stable and to maintain the welfare of the fish. We hope to start operating in 2017, provided we can get the necessary concessions,” Myrebøe says.

THE BEST OF TWO WORLDS

The fish farm is a submerged facility designed almost like a rig. It is an anchor fixed structure floating steadily in the ocean at water depths of between 100 and 300 meters, combining the best of existing technology and solutions from the Norwegian fish farming industry and the oil and gas sector.

While Global Maritime AS has performed the technical design and engineering, MARINTEK was involved in a basin model test to ensure a suitable behaviour of the facility during harsh weather conditions. The design work has been verified by DNV GL through an independent review. Kongsberg Maritime is involved in the project as a result of its unique combination of experience as a supplier to the maritime, offshore and fishery industries.

Systems from Kongsberg Maritime will include sensors and echo sounders for real time visualization of fish distribution in order to monitor such factors as fish biomass, position and escape. In addition, the delivery will include automation, navigation and communication systems for data transfer to shore. Project management and EIT will also be provided as part of the integrated ‘Full Picture’ solution from Kongsberg Maritime.

”All of the key suppliers involved in the fish farm are driven by an enormous enthusiasm and prestige which are the best control parameters in my opinion. We searched for the suppliers who were the most fit to help, and who would be able to provide the technology needed to run this facility in the future. Kongsberg Maritime has a proven record as a supplier to the oil industry and are renowned for having high image quality on subsea products. Among other things, we use sensors from Kongsberg Maritime to measure the size of the fish so that we can see which ones are ready to be harvested,” explains Myrebøe.

A FARM ON THE FISH’S TERMS

Critics have voiced a concern that fish farming might cause several environmental and health issues, and the industry is working hard to find good solutions to these issues. For instance, by placing the facility offshore, the biological conditions are more ideal for aquaculture on the “fish’s terms”. To run a successful fish farm, it is therefore important to find areas with a natural supply of fresh water, such as Frohavet, where the Gulf Stream passes through. This is where the pilot will be located, and despite waves of up to 8-10 metres, the enormous construction is completely stable.

“One of the challenges when a fish farm is placed in a fjord like today, is that the tide washes the same water in and out. This causes problems with lice, since the same population of lice may be washed in and out. In an offshore facility placed in the ideal conditions, the water passes through the cage and washes away lice and other pollutants at the same time, keeping the fauna as natural as possible,” says Myrebøe.

Although lice are a natural part of the ocean fauna, it can be damaging to the fish in large quantities, and other methods are also being tested to avoid the fish catching lice.

“By releasing larger smolt into the facility, the risk of catching a disease is reduced along with the life cycle. Another technique we use is to feed the fish 10 meters below sea level, forcing the fish to go down. This reduces the risk of catching lice since they are located close to the surface. It is also important to place the farms so that water from one facility does not wash into nearby facilities,” Myrebøe explains.

FULLY AUTOMATED

All farming operations can be managed either onboard or remotely, minimizing the use of service vessels and outside equipment, making the entire facility more environmentally friendly. This means that the fish can stay inside the net from stocking to harvestable fish. The facility can be divided into three separate compartments if needed, enabling various fish operations.

The net is fixed to the structure and has an incredible strength in order to prevent fish from escaping. In addition there is an extra net in the surface zone to protect against drifting matters. Regular cleaning of the net is important, and is ensured through automated spray nozzles. Since the facility is fully automated, heavier manual operations are avoided, and the entire facility can be run by a crew of 2-4 people only.

”There has been a lot of interest in working on the farm. We are aiming to have three people onboard at all times, combining competence in biology, electro and instrumentation. The staff will be trained much like offshore staff with emergency preparedness courses for instance,” says Myrebøe.

LOW OPERATIONAL COSTS

While a comparable fish farming facility today has a price tag of approximately 50 MNOK, an ocean farming facility will have a significantly higher investment cost, raising questions of profitability. However, since the operational costs are expected to be lower than other fish farming facilities, the offshore farms may prove to be more profitable in the long run.

“If the fish are doing well, they will grow faster, something which in turn provides larger fish. There are also cost savings to be made on using more advanced and better surveying systems to monitor the fish and the environment on the fish farm. In addition, the operational costs are lower since most processes are automated and only 3 people are required to operate the facility. Maintenance costs are also low as maintenance work can be completed faster than today. The rig will be de-ballasted out of the water to facilitate inspection by experts. The entire operation can be completed in a week,” says Myrebøe.

INCREDIBLY SUSTAINABLE

There is little doubt that this enormous construction, if put into operation, has the capacity to streamline the future of the fishery industry. The world needs more fish protein, and with the enormous resources that our long coastline offers, it is expected that Norway takes a leading role.

“It is important for the future of the world population that this succeeds, and I don’t see why not. The world’s oceans represent more than half of the earth’s biological diversity, and fishery is incredibly sustainable, but only 2% of our caloric intake comes from the oceans. This is therefore an obvious source to feed more people. The Norwegian government has set a goal to increase fish production from one million tonnes to five million tonnes by 2050, so it is time to start thinking differently and to put those thoughts into action,” Myrebøe concludes.