The story behind dynamic positioning

Hailed as the greatest Norwegian engineering achievement since WW2. The secret behind the Norwegian Dynamic Positioning adventure was bold innovation, a willingness to take risks, and a small group of men with a big goal.

-

Text:TARJE HOLTVETD

Photo:FROM THE BOOK "THE JEVEL IN THE CROWN"

-

Ove Ronny HaraldsenGroup Communication Manager

Readers of Norway’s Technical Weekly Magazine recently named dynamic positioning, a technology from KONGSBERG, as the greatest engineering feat in Norway since World War II. This is the story of how it all started:

One November day in 1975, Nils Albert Jenssen was given an assignment that would make his name in Norwegian industrial history: to develop a new control system for dynamic positioning at sea. The system would be unlike anything else and simultaneously set a completely new standard for quality. The principal was Kongsberg Våpenfabrikk (KV). Jenssen was a recently graduated cyberneticist and employed by SINTEF in Trondheim. He and his colleague Steinar Sælid approached the task with enthusiasm. “We didn’t know it was difficult,” recalls Jenssen today. “That must be why it went so well.”

THE PROFESSOR’S DREAM

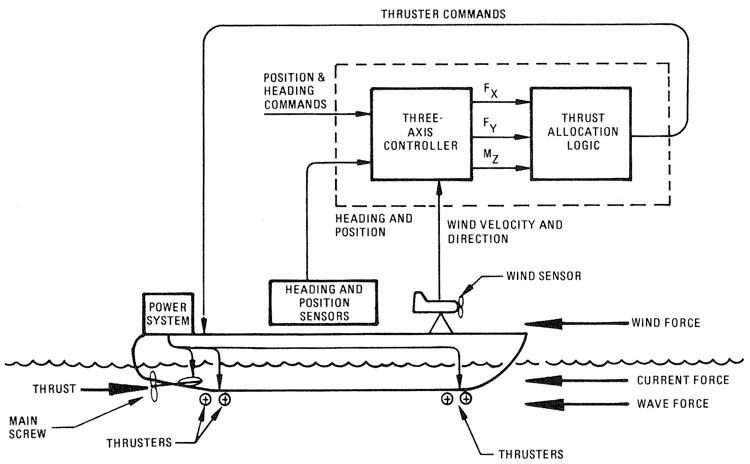

In short, dynamic positioning (DP) helps to keep vessels in place on the water without an anchor. Specially built engines and propellers prevent the wind, currents and waves bringing the vessel out of the desired position.

The earliest attempts at DP were made in the USA in around 1960. A manual DP system was developed to help geologists who were studying the sliding of ocean plates on the seabed. But it was not until the offshore industry started to show an interest in the technology that its development really took off.

Discover industry-leading DP solutions

Our K-Pos Dynamic Positioning Control System benefits from decades of data and development and is a vital element in offshore operations

“By the end of the 1960s most of the basic principles for DP were in place,” says Jenssen. “They had thought through how one should calculate deviations and distribute engine power via regulators. However, they lacked a proper system for controlling all this and thus it did not work very well.

” Early in the 1970s, the doyen of Norwegian cybernetics, NTH’s Professor Jens Balchen, travelled to California to study the American DP systems. He was thrilled by much of what he saw, but thought that it must be possible to do it better.

FROM SCEPTICISM TO INTEREST

Professor Balchen’s idea was to discard the classic control technique and replace it with what he called a model-based control system. This entailed the DP system being based on a mathematical calculation model that understood how a vessel behaves on the water. The whole thing was just in the planning stage, and barely that, when the professor started to sound Norwegian industrial concerns out about whether they might be interested. Unsurprisingly, the response was tepid.

“The companies could not see the benefits,” says Nils Albert Jenssen. “You have to remember that this was before offshore activities really started out in the North Sea. At the time, DP was almost viewed as something that the Americans were playing with and which would not really spread. The companies doubted that the system would find a market.”

KV was not really convinced by Professor Balchen’s vision either. But the professor refused to give up and in 1975 he managed to persuade KV to give it a try - on the condition that a customer could be found who was willing to order the system. The customer who finally came forward was Stolt-Nielsens Rederi. A contract was signed for the delivery of one DP system based on the idea of Professor Balchen. But the idea still only existed in the professor’s head. What remained was to see whether or not it could be realised.

WORRIES AND LONG NIGHTS

“The bear still had to be shot when Stolt-Nielsen bought the pelt,” says Jenssen. “This was a normal way of doing things in this industry at the time. If you didn’t sell the pelt, you never got to shoot the bear.”

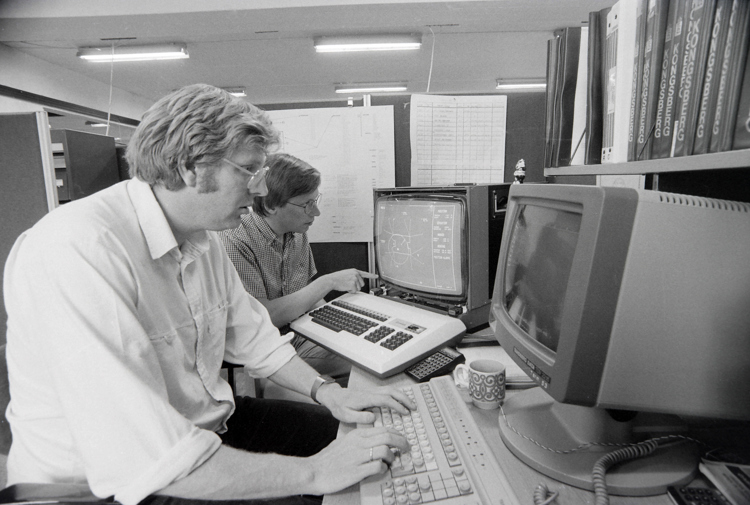

It was decided that a team at KV would be responsible for delivering tangible components such as computers, buttons, panels and displays. At the same time, the SINTEF boys, Nils Albert Jenssen and Steinar Sælid, worked at full speed to develop control algorithms and software. “Altogether there were perhaps ten or twelve men working on the project,” says Jenssen.

“We started in January 1976, almost before the ink was dry on the contract. We had just the deadline and the path. In the space of one year we had to make something that no one had made before us. But the fact that we were such a small team was a big advantage. We avoided wasting time on discussion and could just spend the time working instead.”

The lights were often lit late into the night in the offices of Jenssen and Sælid. Many difficult problems had to be solved. “The theory was fine, we understood that. But almost all of the model- based research that had been carried out on how vessels behave on the water had focused on vessels in movement. Here, the vessel suddenly had to remain still. After a while we realised that it was much harder for a vessel to remain still than it was for it to move,” says Jenssen. “Also, computers couldn’t do that much at that time. We had to simplify everything all the time; simplify, simplify.”

THE BREAKTHROUGH

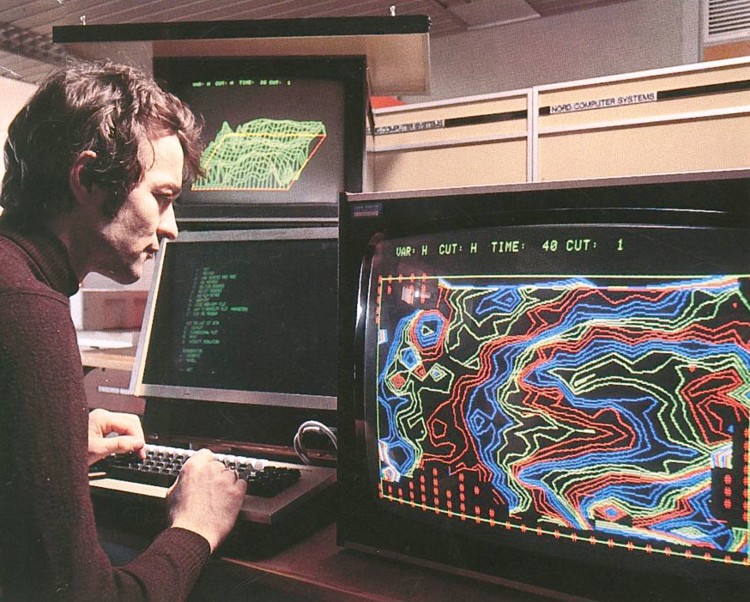

“On 17 May 1977, the new system, which had been named Albatross, was tested live for the first time. It happened on board Stolt-Nielsens Rederi’s vessel ‘Seaway Eagle’. That day has become a milestone in Norwegian maritime industrial history. We got a big kick from the message from ‘Seaway Eagle’ saying that the system worked,” says Jenssen.

“After all, for us this was like a moon landing.” But even though the system was a success, the job was only half done for the engineers who were behind it. A long series of improvements and adjustments now awaited. They also had to spend a lot of time on service as the number of customers grew. “The engineering alone does not explain all of the success of Albatross,” says Jenssen.

“It was also a product made by people who cared a lot. Those of us in the team prided ourselves on developing an extreme service culture for our customers. When a problem arose on a vessel, we actually went to sea to sort it out. You could call it an entrepreneurial spirit.”

WORLD LEADER

Today, Kongsberg is the world leader in dynamic positioning. DP continues to be introduced into new areas, and there is nothing to indicate that demand is going to decrease. The offshore industry as we know it is unthinkable without the use of DP. For his part, Nils Albert Jenssen has been honoured with a Distinguished Achievements Award by the Maritime Technology Society in the USA, and been named an honorary member of the Norwegian Society of Automatic Control (NFA).

“The DP technology we adopted at the start was indeed more successful than we had thought,” says Jenssen modestly. “It has of course been refined over the years. But the principles remain the same.”