Wind Turbine Installation Vessel

Efficiency and safety backed by industry-leading experience

Raise the safety, efficiency, and profitability for your Wind Turbine Installation Vessels. Using decades of experience in offshore operations, we have developed integrated solutions in advanced propulsion, dynamic positioning, deck machinery, and energy management, enabling intelligent operations. Cut your downtime with our unique services such as our Thruster Support Pool and global service network.

Powering performance with proven advantages:

- Unique functionality in dynamic positioning derived from decades in the offshore energy industry

- Future proofing your vessel with design and engineering to handle the largest turbines

- 20 years’ experience ensuring safety and reliability in heavy-lift offshore operation

- Reduced downtime and maintenance costs with comprehensive customer service support

- Robust safety and automation systems developed for complex vessels and offshore operations

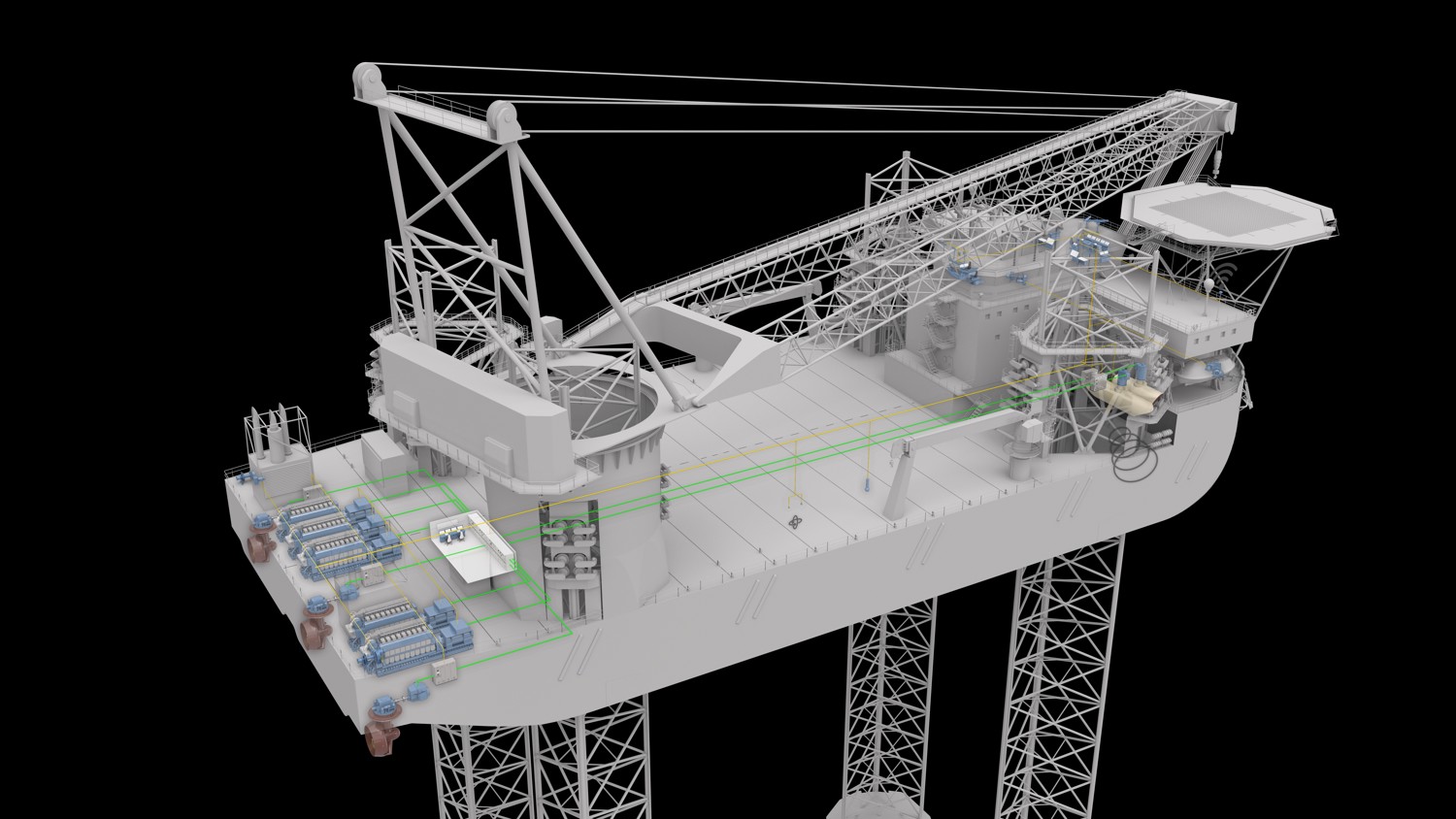

Integrated products and systems for new and retrofit WTIVs

State-of-the-art propulsion units, dynamic positioning, deck machinery, power management, and safety systems working together to create powerful synergies that ensure accuracy, efficiency, and safety.

Experience and innovation for your next WTIV

Stay competitive with products and services backed by decades of experience in the offshore energy sector.

-

Our newest Rim Drive thrusters, popular among offshore wind vessel operators, are highly responsive, going from 0 to 100% RPM in as little as 2 seconds

seconds -

With our unique Thruster Support Pool, downtime for thruster maintenance can be reduced from weeks to just four days.

days -

For 45 years, we have developed customised solutions in dynamic positioning for the offshore industry, giving our clients more efficiency and safer control over operations

30 years

See how we maximise efficiency in wind turbine installation

Kongsberg Maritime helped Cadeler maximise fuel effiency, safety, and reliability with integrated systems and solutions for the WTIV Wind Peak

Lifecycle support

News and media

FAQ

Frequently asked questions about how we ensure safety, profitability and efficiency in wind turbine installation operations

Load handling and vessel positioning are key factors for WTIVs as offshore wind turbines get larger. Our K-Pos Dynamic Positioning has functions developed over decades to meet the evolving needs of offshore energy, including WTIVs. These include specific functions for Jack-Up vessels that help operators during the transition from DP station-keeping and leg deployment. Our DP systems also come with specific, heavy-lift functions that offset instabilities during very heavy lift operations. Such capabilities will be vital as turbines get larger.

We are also investing in new vessel designs suited for the offshore wind market. In 2023, we introduced a new Anchor Handler vessel design that can support offshore floating wind. Our R&D work in this field will continue to meet future demands by our clients.

Our intelligent solutions in power management help cut fuel use, particularly for vessels in the offshore sector. As part of a complete energy management system, our EcoAdvisorTM solution, developed in conjunction with Sintef, NORCE, and Innovation Norway, can help reduce fuel consumption in DP vessels by as much as 15%.

In addition to specific power and energy management tools we offer, our range of thrusters provide energy-efficient operation and are increasingly enabled for battery operation.

Our scalable ship automation systems have special applications for Power Management, Energy Management, battery hybrid applications, gas handling system, fuel supply systems, and safety systems allow for alternative fuels, thus future-proofing vessels.

Maintenance is a key factor in the overall Opex of a vessel and downtime needs to be reduced as much as possible to ensure maximum profitability. We have several programmes that, together, create an intelligent maintenance system that dramatically cuts downtime.

Our Thruster Support Pool, which quickly supplies our clients with 100% refurbished thrusters from a collective pool, can reduce thruster maintenance time from weeks to days. Our Remote Support system allows our engineers to remotely access our equipment, to help your personnel fix issues quickly without any travel delays.

Our maintenance programmes are supported by K-CMS, condition monitoring solution, which provides in-depth data on all rotating equipment and allow for smart maintenance planning. All of this reduces downtime and therefore, the cost of maintenance.