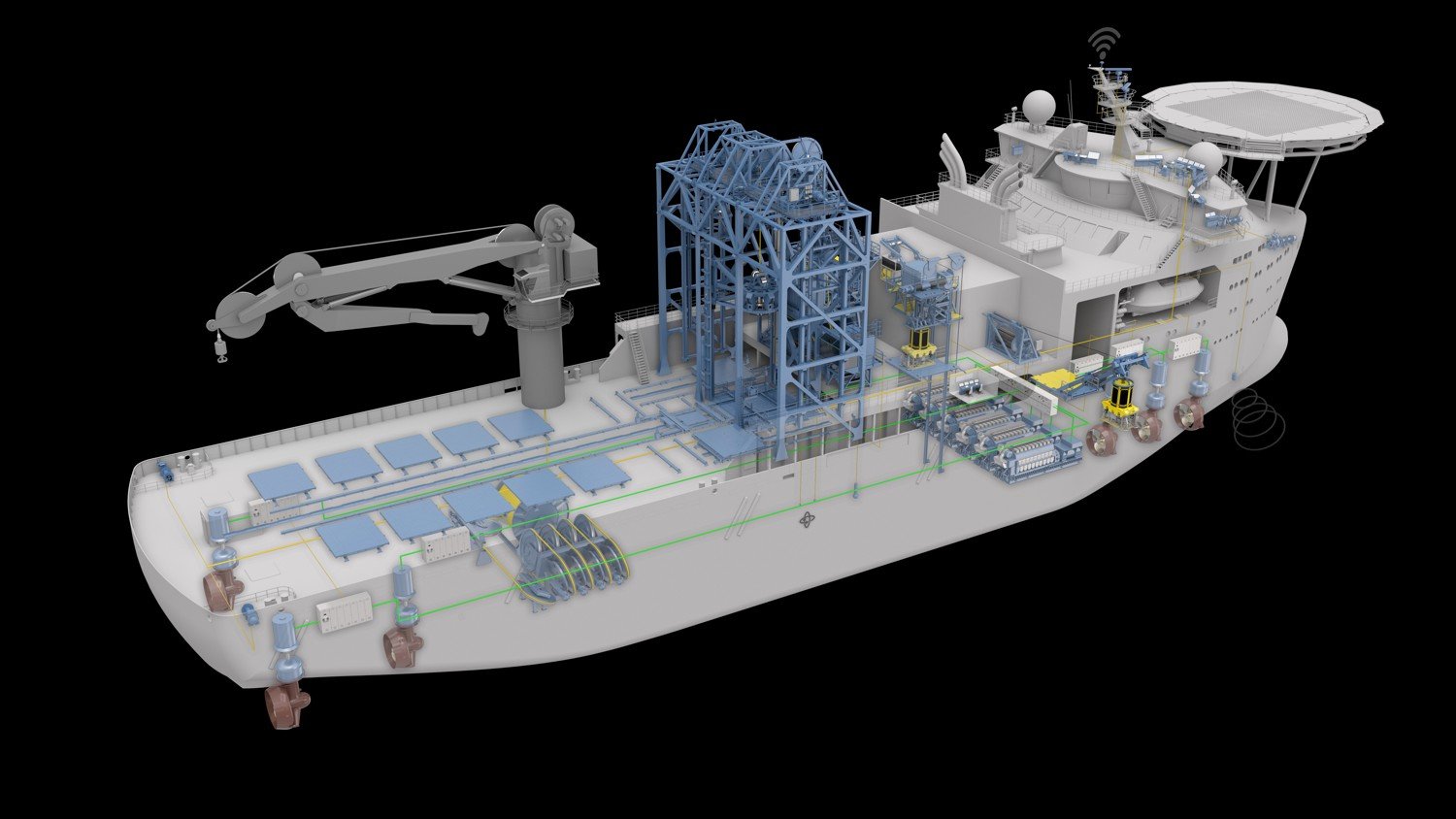

Offshore construction vessel

Efficient deck spaces and excellence in station-keeping

Boost efficiency, versatility, and sustainability with innovative solutions. Handle complex offshore tasks such as anchor installation, mooring, cable work, and project construction while ensuring compliance with strict regulatory standards. Achieve future-proof performance for evolving industry demands.

Powering performance with proven advantages:

- Customised functionality in dynamic positioning with our K-Pos DP control systems

- Hybrid power solutions that offer up to 20% fuel savings

- Advanced launch and recovery systems for all ROVs from one of the world’s largest suppliers

- Dedicated ship design services for efficient new build construction

- Experienced refit services to extend the working life of older vessels

- Robust cybersecurity measures backed by third-party verification

Integrating systems and solutions for efficiency and reliability

By understanding and integrating operations, energy, and handling solutions, we unlock powerful benefits for owners and operators.

Maximise offshore efficiency, versatility, and sustainability

Our advanced solutions empower you to optimise operational efficiency, expand vessel capabilities, and ensure future-proof performance. By streamlining offshore tasks, boosting vessel utilisation, and staying ahead of evolving industry demands, you can reduce costs, meet regulatory standards, and drive long-term value for your offshore projects.

-

Streamline offshore tasks to reduce downtime and ensure faster project completion, ultimately boosting your ROI.

Optimise operational efficiency -

Integrate cutting-edge technologies to enable your vessels to handle a broader range of operations independently, enhancing versatility.

Expand vessel capabilities -

Comply with the latest environmental regulations, minimising emissions and fuel consumption while securing long-term operational viability.

Ensure regulatory compliance -

Adopt sustainable, adaptive solutions that keep your vessels at the forefront of offshore construction capabilities for evolving industry demands.

Future-Proof your operations

Comprehensive offshore system and solutions for optimal performance

Kongsberg Maritime offers a full suite of advanced systems and solutions designed to enhance the operational efficiency, safety, and sustainability of offshore projects. From cutting-edge vessel technologies and mooring systems to versatile deck machinery and propulsion solutions, we empower you to optimise performance, meet regulatory demands, and maximise the value of your offshore operations, now and in the future.