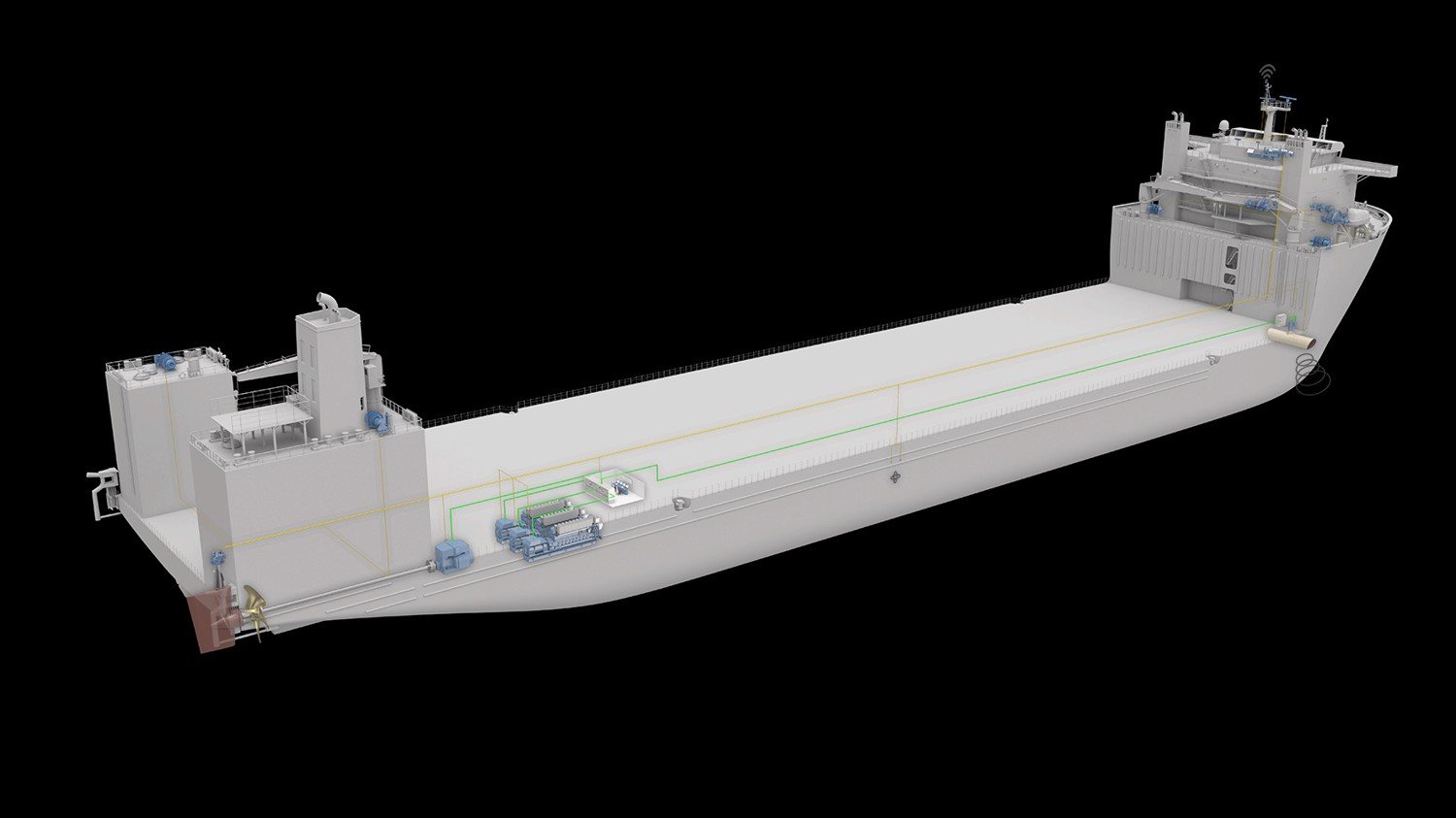

Heavy lift vessel

Engineering excellence for accuracy and safety in critical operations

Maximise the safety and efficiency of your heavy lift operations, even in challenging conditions. Our DP control systems support a wide range of heavy lift operations, from small crane operations to complex buoyancy lifts. With customised functions tailored to your exact needs, vessels can conduct heavy lift operations precisely and safely, regardless of sea state. We seamlessly integrate state-of-the-art propulsion, deck machinery, bridge and navigation, and control and safety systems to ensure optimal performance. Our advanced automation systems minimise risk and maximise efficiency, while our condition monitoring and service support solutions minimise downtime.

Powering performance with proven advantages:

- Superior heavy lift functionality in the K-Pos dynamic positioning control systems

- Maximised fuel savings and minimised cost with our tailored power and energy management solutions

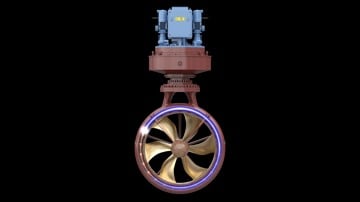

- Greater operational range with our customised propulsion solutions

- Minimised downtime with pro-active vessel condition monitoring

- Increased safety and efficiency with our advanced K-Chief vessel automation system

Integrated solutions for heavy lift vessels

We maximise the efficiency, safety, and reliability of your lifting operations with systems that combine precision vessel control with lift capability.

Reliable, robust systems and support

Yards and owners trust us for unmatched engineering support, ensuring easier-to-build and operate heavy lift vessels with unwavering safety and precision.

-

For almost half a century, we’ve developed customised functions, including heavy lift and heave compensation functions, to meet, and often exceed, the needs of our offshore customers.

35 years -

The K-Chief vessel automation system can effectively integrate at least five or more onboard systems into a single platform, reducing maintenance time and training requirements.

in 1 -

Thruster maintenance downtime can be reduced to as little as four days thanks to our unique Thruster Support Pool.

days