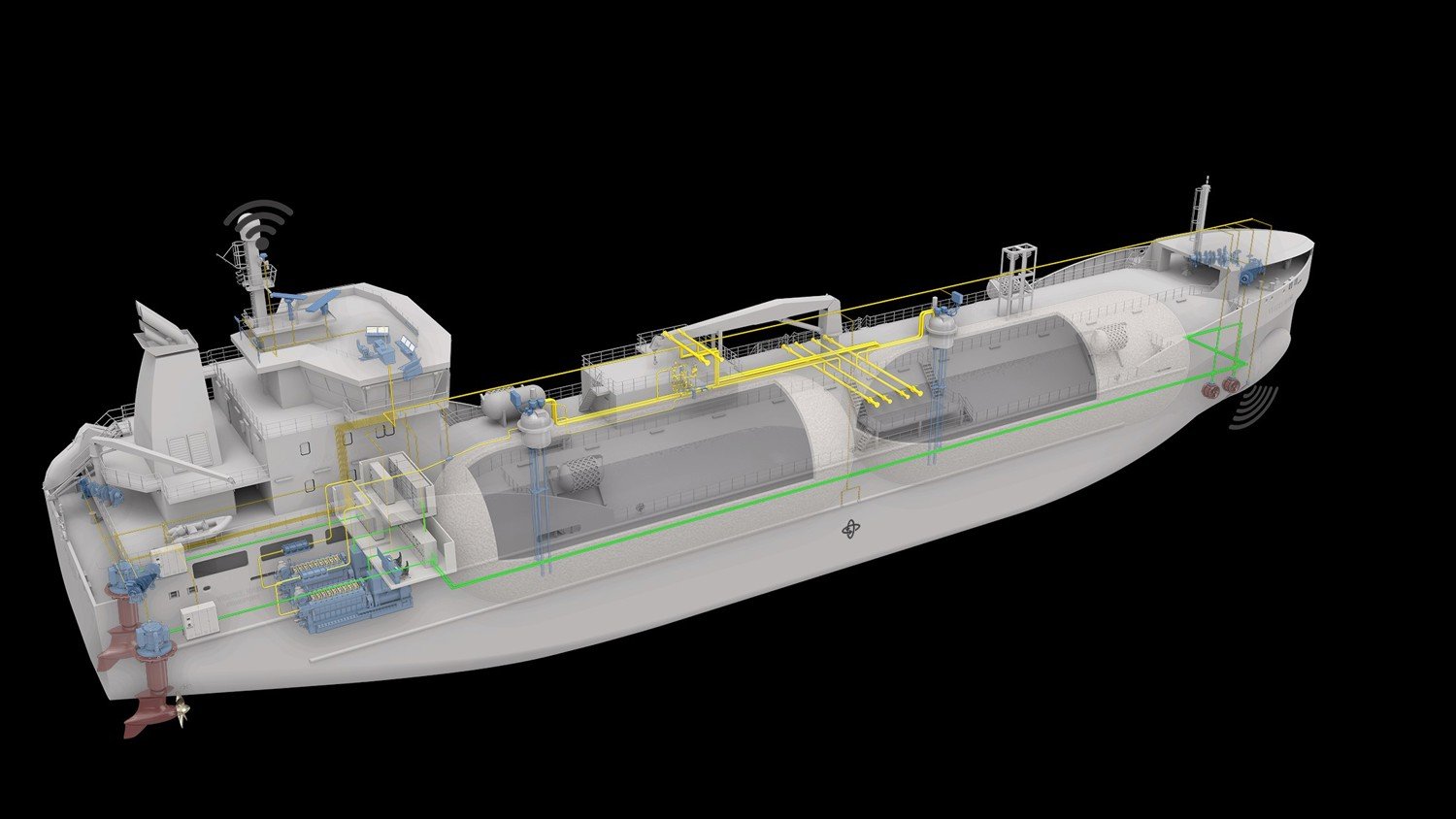

Small scale LNG vessel

Industry-leading LNG transfer and monitoring systems

Our LNG expertise, refined through close customer collaboration, delivers unmatched accuracy, safety, and reliability for your small-scale operations. These are integrated with our advanced cargo monitoring, information management, and automation systems. As your trusted partner, we ensure safe docking and harbour operations with cutting-edge manoeuvring and collision avoidance capabilities. For owners wanting new vessels, our small-scale LNG carrier designs leverage decades of experience for optimal efficiency and performance.

Powering performance with proven advantages:

- Unified control of your entire LNG operation for simplified maintenance, time and resource efficiency.

- Ready-to-go design for small-scale LNG carriers for efficient new builds.

- Class-certified safety systems for reduced risk in LNG operations.

- Highly accurate radar-based cargo management and transfer systems to minimise loss, maximise profit.

- Collision avoidance and automated docking for enhanced safety and efficiency.

Integrated solutions for optimal performance

Ensuring efficiency, safety, and reliability with proven systems for LNG operations as well as vessel control and performance.

Industry leadership in LNG systems and handling

Our market share and experience in LNG carrier technology ensures reliability, safety, and efficiency in every new build or refit project

-

Today, over 700 LNGCs, FSRUs, and LNG bunker vessels are at sea with our LNG systems, with 200 more due for delivery

685 vessels -

Our radar-based level gauging systems and custody transfer systems (CTS) have been in operation since 1989. Our unique AutroCAL® function is the first fully automated calibration and verification method on the market.

1974 -

In the 2020s, our custody transfer systems were installed on 240 of the 242 new-build LNG carrier vessels, or 96%, a sharp rise from 71% as of 2000.

81%

Engineering solutions for LNG carriers

Our custom solutions and lifecycle support for owners and operators ensure safety and reliability for LNG maritime operations.

Lifecycle support

LNG News

FAQ

Emissions, design, and operations in small-scale LNG carriers

We have a highly experienced team handling conversions, retrofits, and refits for all vessel types and ship designs.

We can help older vessels prepare for compliance with new regulations, improve overall performance, and make operations more sustainable. This lengthens the working life of a vessel.

The scope of a retrofit project can range from new propulsion systems or hybridisation up to a new vessel purpose.

Through re-engineering of systems, a KM solution optimises vessel performance by increasing system efficiencies and reducing operational costs. We use sophisticated software and tools to simulate and test new equipment, hull structure and seaworthiness.

We can work directly with shipyards to coordinate design, engineering, production and yard installation. Your project is fully taken care of until the vessel is back in the water.

We also verify the results of the project with data gathered from vessel equipment and look for potential improvements.

A small-scale LNG trading operation is an integration of the handling of liquid gas between charterer / owner and clients. Our knowledge of handling liquefied gas combined with our Information Management Systems provide the industry with a precise overview of the energy transfer between the parties.

We provide the engineering and services to link together all parties in the LNG value chain. We give the whole Gas Value Chain a better definition of energy transfers and commercial value.