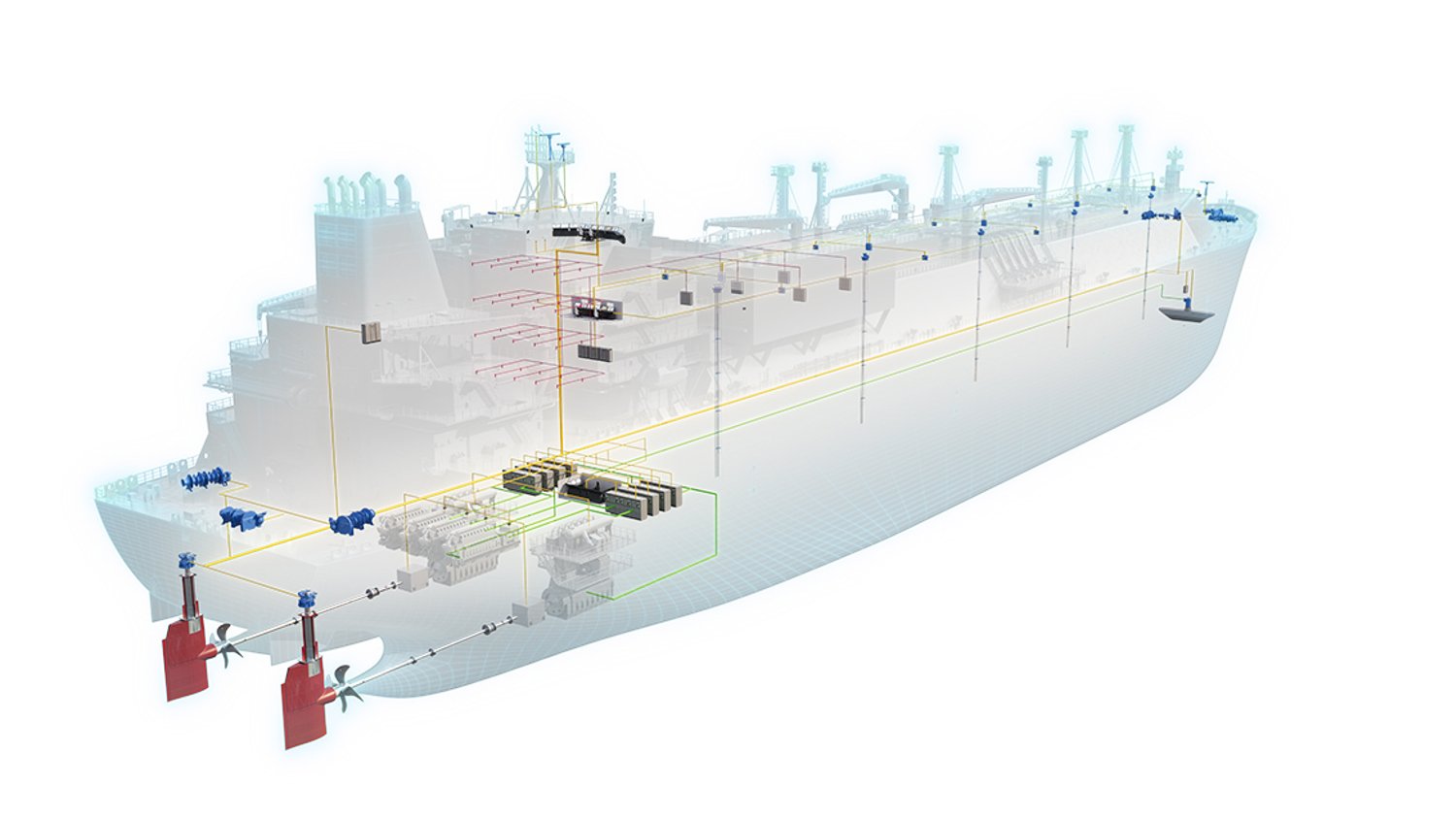

LNG carrier vessel

Efficient solutions for a cleaner, safer LNG future

For more than 20 years, we’ve partnered with LNG carrier owners and shipyards for safe, efficient operations. Our integrated systems for new builds and refits maximise performance, minimise emissions, and ensure safety throughout the vessel's lifecycle. Our advanced automation, cargo monitoring, handling, and energy management systems all ensure reliable and sustainable LNG operations.

Powering performance with proven advantages:

- Unified control of your entire LNG vessel for simplified maintenance, using our industry-leading marine automation system.

- Seamless integration of LNG operational data across all 3rd party providers for a complete overview with K-IMS.

- Reduced risk of interruptions in your LNG operations with our class-certified safety systems.

- Extremely accurate cargo management and transfer, using high-precision radar technology for minimal loss with K-Gauge.

- Highly experienced team of LNG specialists in key locations around the world, providing local support.

Integrated solutions for LNG carriers:

We ensure efficiency, safety, and reliability, with systems that combine vessel control and performance with LNG operations

Industry leadership in LNG systems and handling

Our market share and experience in LNG carrier technology ensures reliability, safety, and efficiency in every new build or refit project

-

Today, over 700 LNGCs, FSRUs, and LNG bunker vessels are at sea with our LNG systems, with 200 more due for delivery

685 -

Our radar-based level gauging systems and custody transfer systems (CTS) have been in operation since 1989. Designed for LNG carriers, the CTS provides reliable accuracy. Our unique AutroCAL® function is the first fully automated calibration and verification method on the market.

1974 -

In the 2020s, our custody transfer systems were installed on 240 of the 242 new-build LNG carrier vessels, or 96%, a sharp rise from 71% as of 2000.

81%

Full lifecycle support

FAQ

Emissions reduction, refits and retrofits, safe operations and more for LNG carriers

We have a highly experienced team handling conversions, retrofits, and refits for all vessel types and ship designs.

We can help older vessels prepare for compliance with new regulations, improve overall performance, and make operations more sustainable. This lengthens the working life of a vessel.

The scope of a retrofit project can range from new propulsion systems or hybridisation up to a new vessel purpose.

Through re-engineering of systems, we boost vessel performance by increasing system efficiencies and reducing operational costs. Uniquely, we can simulate and test new equipment, hull structures, and seaworthiness with use using sophisticated advanced proprietary software and tools.

We work directly with shipyards to coordinate design, engineering, production, and yard installation. Your project is fully taken care of until the vessel is back in the water.

We also verify the results of the project with data gathered from vessel equipment and look for potential improvements.

LNG boil off, also known as LNG aging, occurs when LNG is transferred or transported by vessel. Heat ingress or even movement of the LNG inside tanks can cause boil off. This leads to a change in composition that affects the volume and quality of LNG upon arrival at destination. Estimates of boil off rate for LNG during seagoing transportation are as much as 0.15% of total volume per day.

Improvements in ship design and engineering can help mitigate this problem, but it will never entirely go away. We offer an onboard solution called LNG Aging. This application, available on the Kongsberg Maritime Information Management System (K-IMS), lets operators quickly analyse and calculate the consequences of different options for LNG transport that may minimise LNG boil off.

For example, reducing or increasing speed with respect to aging of LNG compositions and boil off rate, or rerouting vessels to different terminals while ensuring that requirements are met with respect to LNG compositions, can be managed with the application.

The K-IMS LNG Aging application suite consists of an Online and Offline module featuring user-friendly interfaces. The Online module includes an LNG Aging Prediction application that uses a vessel’s live data to show current and predicted LNG compositions for selected dates. When changing the selected dates, the application automatically recalculates the LNG aging and compositions.