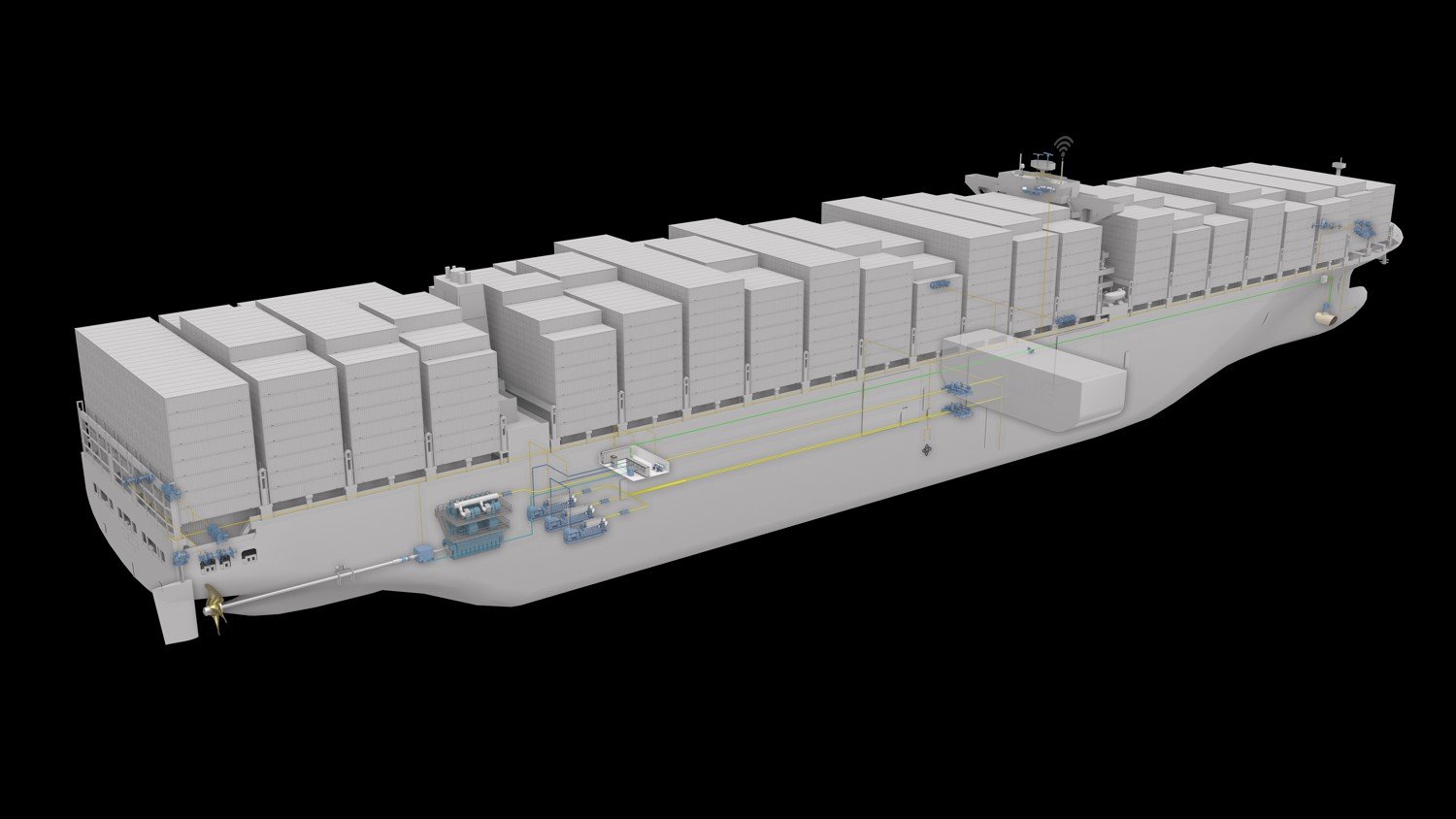

Container vessel

Cutting emissions and fuel costs in container shipping

Our fully integrated solutions span bridge, propulsion, navigation, planning, reporting and maintenance systems. This secures long-term operational and overall fleet management performance. We support the transition to LNG, which provides big cuts on emissions, while allowing for a future transition to zero-carbon fuels.

Powering performance with proven advantages:

- Integrated solutions for container feeder vessels

- Integrated Navigation Systems for best route planning

- Wind-assist solutions and installation for any operational profile

- Life-cycle support services to ensure your vessel runs at best performance for longer

Integrated solutions that cut emissions:

Our holistic solutions help container vessel owners gain maximum efficiency and make the switch to LNG

How we cut emissions from carrier vessels

-

Our Power Take Off solution PTO contributed to OPEX savings of ~1.5-2% on a study we conducted on a theoretical 14,000 TEU container vessel operating an Asia-Europe route.

% -

With our future-proofed LNG dual fuel option, container vessel owners have the option of two conventional fossil fuels and four low-carbon options, including HVO and ammonia.

fuels -

Our LNG Fuel Gas Supply System offers vessel owners a reduction of up to 24% in carbon emissions, with SO2 and particulate emissions reduced to almost zero.

9%

Lifecycle support

News

Frequently asked questions

Raising efficiency, safety, and sustainability for container vessels

Our container vessel solutions are designed to create optimal performance, efficiency, and sustainability. Key features include:

- Advanced Automation Systems: Enhance operational efficiency and safety.

- Energy Management Solutions: Minimize fuel consumption and emissions.

- Integrated Navigation Systems: Provide precise route planning and monitoring.

- Propulsion and Thruster Systems: High-efficiency thrusters and propulsion options for enhanced maneuverability.

- Environmental Compliance: Systems designed to meet international environmental regulations, including ballast water management and emissions control.

We improve fuel efficiency through several key technologies:

- Energy Management Systems (EMS): Optimise power distribution and consumption across the vessel.

- Efficient Propulsion Systems: High-efficiency thrusters and engines reduce fuel consumption.

- Hull and Propeller Optimisation: Advanced designs reduce drag and improve hydrodynamic efficiency.

- Real-Time Monitoring: Continuous monitoring and adjustments to operational parameters to ensure optimal fuel usage.

We help owners reduce their environmental impact with these technologies:

- Emission Reduction Technologies: Including scrubbers and selective catalytic reduction (SCR) systems to minimize NOx and SOx emissions.

- Ballast Water Management Systems: Prevent the spread of invasive species through compliant treatment systems.

- Energy Efficient Operations: Systems designed to lower fuel consumption and carbon emissions.

- Use of Environmentally Approved Lubricants (EAL): Reduces the environmental footprint of vessel operations.

Our extensive support and services include:

- Global Service Network: 24/7 support and maintenance services worldwide.

- Remote Monitoring and Diagnostics: Real-time monitoring and troubleshooting capabilities.

- Training and Simulation: Comprehensive training programmes for crew and operators using state-of-the-art simulators.

- Lifecycle Management: Tailored service agreements for maintenance, upgrades, and spare parts management.

Kongsberg's systems are designed to comply with the latest international maritime regulations, including:

- IMO Tier III Compliance: Systems and solutions meet or exceed emission standards.

- Ballast Water Management Convention: Solutions comply with stringent ballast water discharge standards.

- Energy Efficiency Design Index (EEDI): Equipment and vessel designs adhere to energy efficiency requirements.

Yes, Kongsberg offers tailored solutions to meet specific operational and technical requirements of different container vessels. Customisation includes:

- System Integration: Seamless integration with existing systems and new installations.

- Scalable Solutions: From small to large vessels, systems can be scaled to meet specific needs.

- Modular Designs: Flexible configurations to accommodate varying vessel sizes and types.