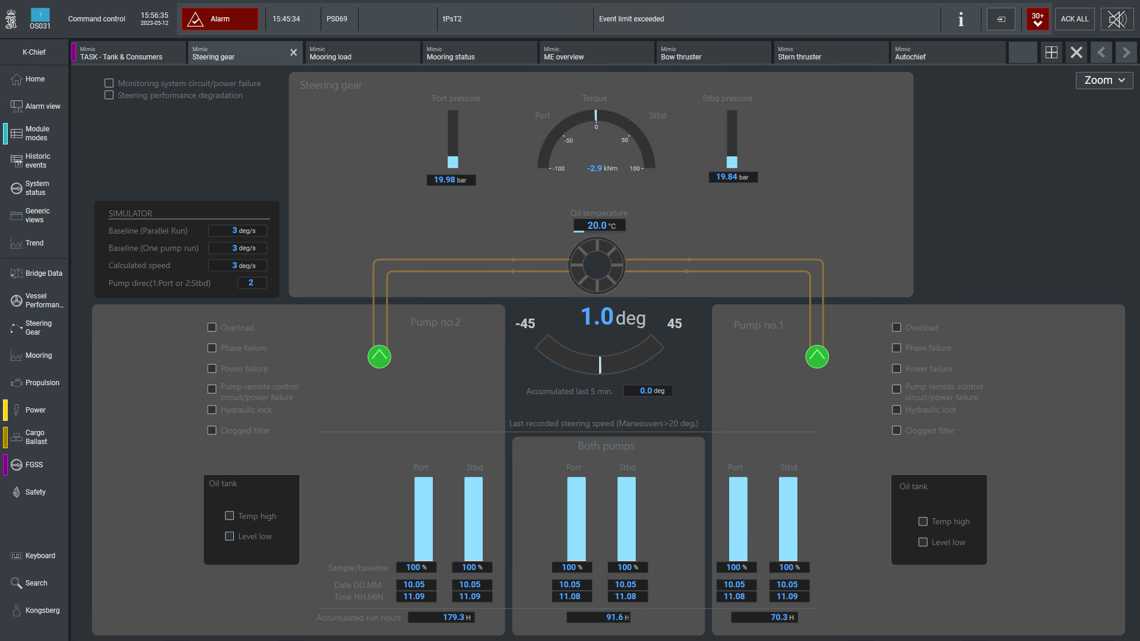

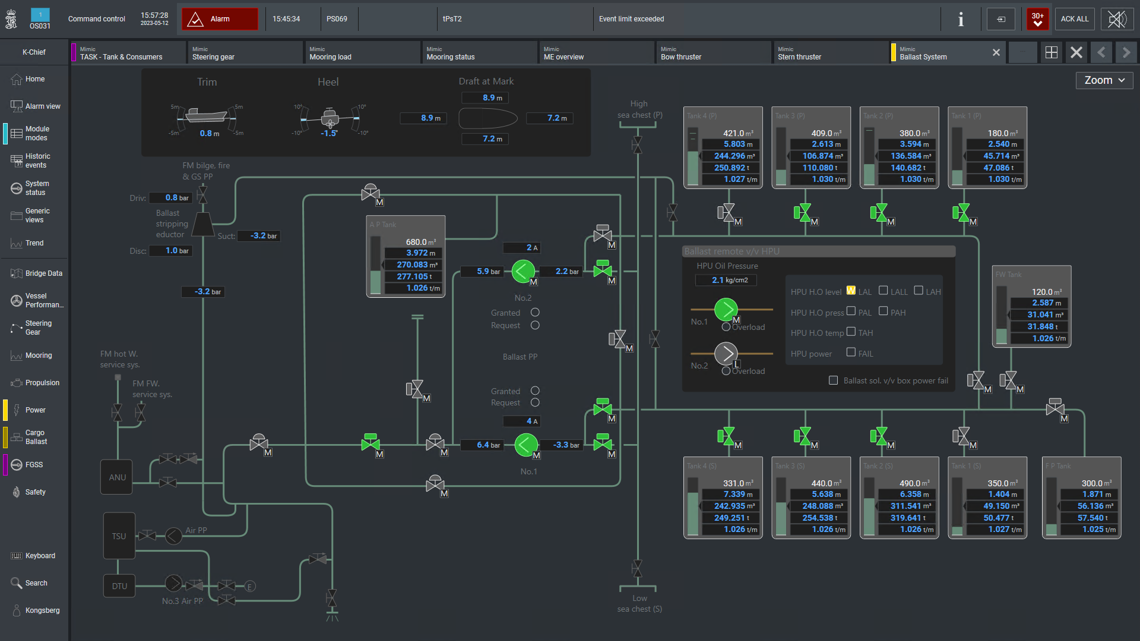

Vessel automation system, K-Chief

Experience next-level efficiency with our latest K-Chief technology, building on the success of K-Chief 600 and K-Chief 700

Our latest generation K-Chief Automation System builds on 50 years of

experience in making safe, reliable and user friendly automation systems

focused on marine usage. K-Chief vessel automation offers the simplicity and

robustness of our merchant range coupled with the flexibility of our offshore

range ensuring a system suited for the challenging demands of shipyards, ship

owners and professional users world wide.

Vessel automation system

- Installation friendly

- Reliable Operation

- Intuitive use

- Powerful control algorithms

- Built-in configuration

system - Approved for safety

applications

Key features

-

1.

K-Chief offers cost effective standard solutions with the possibility of tailoring to individual requirements. Modular design allows flexibility in configuring the system, covering the whole range from low complexity alarm systems to highly integrated control and monitoring systems.

-

2.

The K-Chief system covers all important functions onboard avessel, and is configurable for all ship types, including oil/LPG/LNG tankers, bulk carriers, container ships, cruise and ferries, yachts, offshore vessels, drilling rigs and other special purpose vessels.

-

3.

The K-Chief complies with the requirements of IMO, local maritime authorities, IACS and holds type approval for major classification societies.

K-Chief is an all-in-one marine automation system combining innovation, safety, and efficiency.

Erik Korssjøen, Product Director Vessel Control Systems, Kongsberg MaritimeK-Chief is a popular and proven marine automation system, and this latest version combines the strengths of our existing platforms to provide shipowners and operators with a better technical and operational solution, and improved integration when they’re selecting more than one system from KONGSBERG. It provides the basis for one common platform on board the ship to integrate the KONGSBERG equipment. For the crew, this simplifies operations making their job more efficient, easier and safer.

The complete marine automation system operated through one common interface

Safeguarding On-board and Outward Ship Connectivity

Data protection and security of the vessel’s connection to the outside world are crucial to address to prevent potentially critical disruption and data leakage.

Our systems:

- Developed and approved to meet the required standard for cyber security compliance.

- Class-approved according to the requirements for cyber-security through a robust, layered cyber-protection method.

The most uniform, seamless and efficient solution in the market

-

Optimised design

- Shared technology

- Common hardware components

- Reduced need for on-board spareparts

-

Installation benefits

- Time-efficient commissioning and sea trial/ testing

- Online update of software»

- One point of contact/ service engineer for the intire installation

-

Ease of operations

- Common point of operation

- Reduced training need

- Simplified maintanence

- Remote support available

Unmatched Services and Support for K-Chief Marine Automation System

-

24/7 Assistance:

Access round-the-clock technical support to resolve issues swiftly and minimize downtime.

-

Spare Parts and Repairs:

Ensure seamless operations with readily available spare parts and expert repair services.

-

Training and Certification:

Enhance your crew's proficiency with specialized training and certification programs designed to maximize the system's capabilities.

View technical fact sheets

Our marine automation systems:

The New K-Chief: Frequently Asked Questions

No, Kongsberg Maritime will still offer spares and service support for K-Chief 600 and K-Chief 700 systems running on Windows 10 platform throughout the product lifecycle.

We have divided the product lifecycle into four phases, and we base our customer support in accordance with those phases. The first is the Utilisation phase, in which we are able to provide full development work on new functionality and provide complete support. The next phase is Maintenance, in which we continue to provide full client support, but with reduced development capabilities. At later stages, when a product enters the Limited Maintenance or Obsolete phases, it becomes more challenging to provide full software and hardware support. At some point, we may no longer be able to source vital components or computers capable of running Windows 10. During the late life cycle phases, clients can expect replacement-kit/upgrade recommendations.

K-Chief 600 and 700 are still in the Utilisation phase, so new and existing customers can expect the same level of support as before.

These systems are in a later stage in their life cycle (see previous answer). We suggest you contact your local Kongsberg Maritime representative or email us at for more information on the support we offer to such products.

We will provide recommendations to mitigate operational risk for your vessels. In addition, our service and support allow integration and upgrades to earlier systems that are quick, pain free and with reduced cost.

The new K-Chief system will become available in 2024 as a Performance Upgrade Solution, in which we replace the Human Machine Interface (the operator station, the computers and panels, and the segment controllers). This is like a mid-life upgrade that really benefits the operator of the vessel.

This means that the new K-Chief system will be compatible with the existing K-Chief 600/700 process net (IO modules), which may be re-used in such an upgrade. In fact, the new K-Chief has been developed with the aim of reusing as much as hardware possible from previous generations. This allows us to offer smart and cost-efficient upgrades and solutions that give maximum benefit to our customers without too much disruption.

Systems with Windows 7 (which were delivered until 2018) will still be supported, but with recommendations to upgrade the existing K-Chief 600 or K-Chief 700 system with new computers running on Windows 10 platform. However, it is still possible for us to upgrade the computers and related software while leaving the existing hardware and technology in place. Please contact us for more details about these solutions.

K-Chief uses both CAN-Bus and R-Bus. The two IO ranges and bus systems will exist in parallel for the foreseeable future. The next generation of IO units are planned to be available in both CAN-Bus and R-Bus versions and the next generation remote controller unit (RCU) will have both CAN-Bus and R-Bus capabilities.

We might see CAN-Bus versions of the next generation products dominating the volume of deliveries, but we don’t know this for sure yet. Our components normally have a lifespan of at least 10 years, so we expect to offer full support for R-Bus for the foreseeable future.

The introduction of the new K-Chief will not change our support commitments made to previous versions of K-Chief because we make service and support commitments according to our lifecycle policy. K-Chief 600/700 will continue to be sold in the Utilisation phase during the transition year of 2024.

The new K-Chief is already launched on Windows 10 and Windows 11 Long Term Support Channel (LTSC) is not yet available at this time. When Windows 11 LTSC becomes available, which is expected late 2024, we will evaluate a change. However, the qualification of a new Windows version for all our systems is a process of six to 12 months, so any change would not be effective until mid-2025 at earliest. For us, the stability of the operating system is more important than the novelty.

KONGSBERG launches unified and simplified K-Chief

Kongsberg Maritime has today unveiled its new K-Chief marine automation system, offering ship owners more efficient operations from a single platform to integrate all KONGSBERG equipment on board.