Expand Offshore Capabilities with Our Mooring Solution for OSCVs

Unleash the full potential of Offshore Construction Vessels (OSCVs) with an innovative mooring solution that maximizes efficiency, safety, and operational versatility. Equip your fleet to handle complex mooring installations independently and stay ahead in offshore operations.

Innovative mooring solution for offshore construction vessels

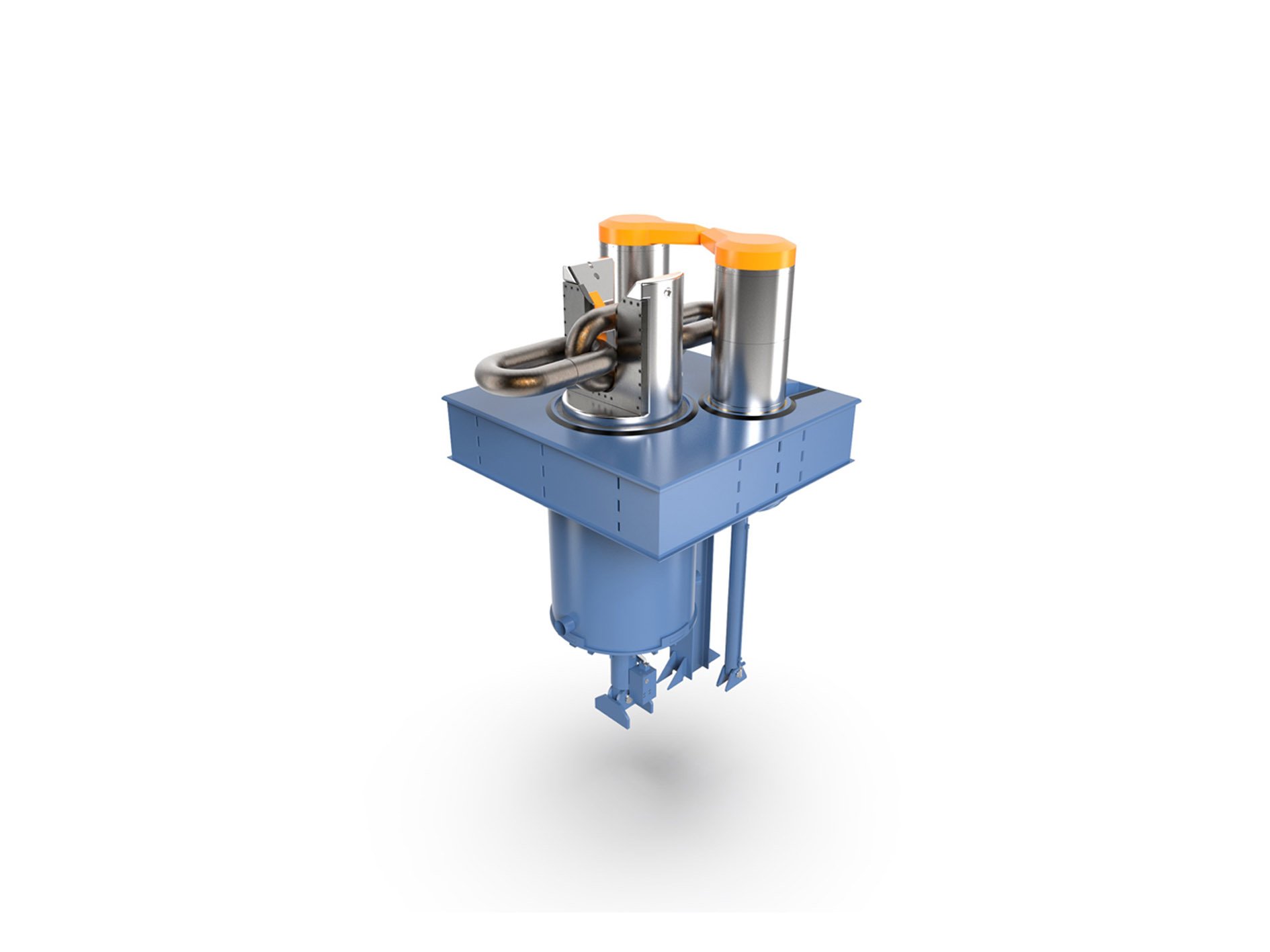

Kongsberg Maritime’s advanced mooring solution for OSCVs enhances vessel capabilities, enabling independent large-scale mooring installations with a purpose-designed anchor handling winch, shark jaws, and stern rollers. Maximise vessel efficiency, safety, and cost savings with our cutting-edge technology.

-

Carry out more mooring operations without the need for additional vessels, reducing downtime and improving field efficiency.

Extended operational window -

Achieve synergies for field developers by expanding OSCV capabilities, leading to lower operational costs.

Cost efficiency -

Enable safer and more efficient over-stern deployment of mooring lines, commonly used in AHTS vessels.

Safety and efficiency -

Choose between permanent or portable winch installation, with the added benefit of permanently fitted shark jaws and stern rollers. Benefit from versatile equipment to optimise performance on every project.

Flexible and versatile installation options

Essential deck equipment for efficient mooring operations

Maximize Offshore Efficiency: Your Questions Answered

Explore how Kongsberg Maritime’s innovative mooring solution transforms Offshore Construction Vessels (OSCVs). Discover the key benefits, operational enhancements, and flexible installation options that keep your fleet ahead in offshore operations.

Our mooring solution delivers significant cost savings by enabling Offshore Construction Vessels (OSCVs) to carry out complex mooring installations independently. With integrated equipment like anchor handling winches, shark jaws, and stern rollers, vessel owners can reduce the need for additional support vessels, minimizing downtime and lowering the solution significantly adds to the versatility of the vessel for a relatively low capital investment.

Yes! By equipping OSCVs with advanced mooring equipment, they can handle larger-scale operations on their own, which means fewer vessels are required for support. This directly reduces vessel chartering and operational costs, resulting in long-term savings.

The option for both permanent and portable installations provides flexibility for different project needs, allowing owners to optimize their vessel configurations based on specific tasks. This adaptability ensures that you only invest in what’s necessary for each operation, cutting down on unnecessary expenditures.

The initial investment in Kongsberg Maritime’s mooring solution is offset by long-term cost savings through improved operational efficiency, fewer vessel requirements, reduced downtime, and enhanced safety. Over time, these benefits lead to significant savings and improved profitability for vessel owners.

By enabling OSCVs to perform mooring operations independently, our solution minimizes the need for additional vessel mobilization. This reduces delays, optimizes time spent on-site, and improves overall field efficiency—leading to lower operational costs and faster project completion.

-

The solution offers several benefits, including:

- Extended operational window: Enables OSCVs to perform more mooring operations independently, reducing downtime and enhancing operational efficiency.

- Cost efficiency: Reduces the need for additional vessels, lowering overall operational costs.

- Safety and efficiency: Provides safer, more efficient mooring line handling, especially for over-stern deployment.

- Flexibility: Offers both permanent and portable winch installation options, adapting to specific project needs.

-

The solution offers both permanent and portable installation options for the winches. Shark jaws and stern rollers are permanently fitted, providing reliability and optimal performance on every project.

This system is capable of handling various types of mooring lines, including those typically used in AHTS (Anchor Handling Tug Supply) vessels. The versatile equipment ensures efficient and safe handling of both permanent and temporary mooring lines.

While the solution is optimized for newbuild vessels, retrofit possibilities can be explored based on vessel specifications and operational requirements.

Our mooring solution helps reduce environmental impact by increasing operational efficiency, reducing the need for additional support vessels, and decreasing operational downtime. This contributes to a more sustainable and environmentally friendly offshore operation.

The UT 7625 design is an advanced vessel design that integrates the purpose-built anchor handling winch, shark jaws, and stern rollers, allowing OSCVs to handle complex mooring operations independently. This design maximizes operational safety, flexibility, and cost-efficiency, enabling OSCVs to perform a broader range of tasks without the need for additional support vessels.