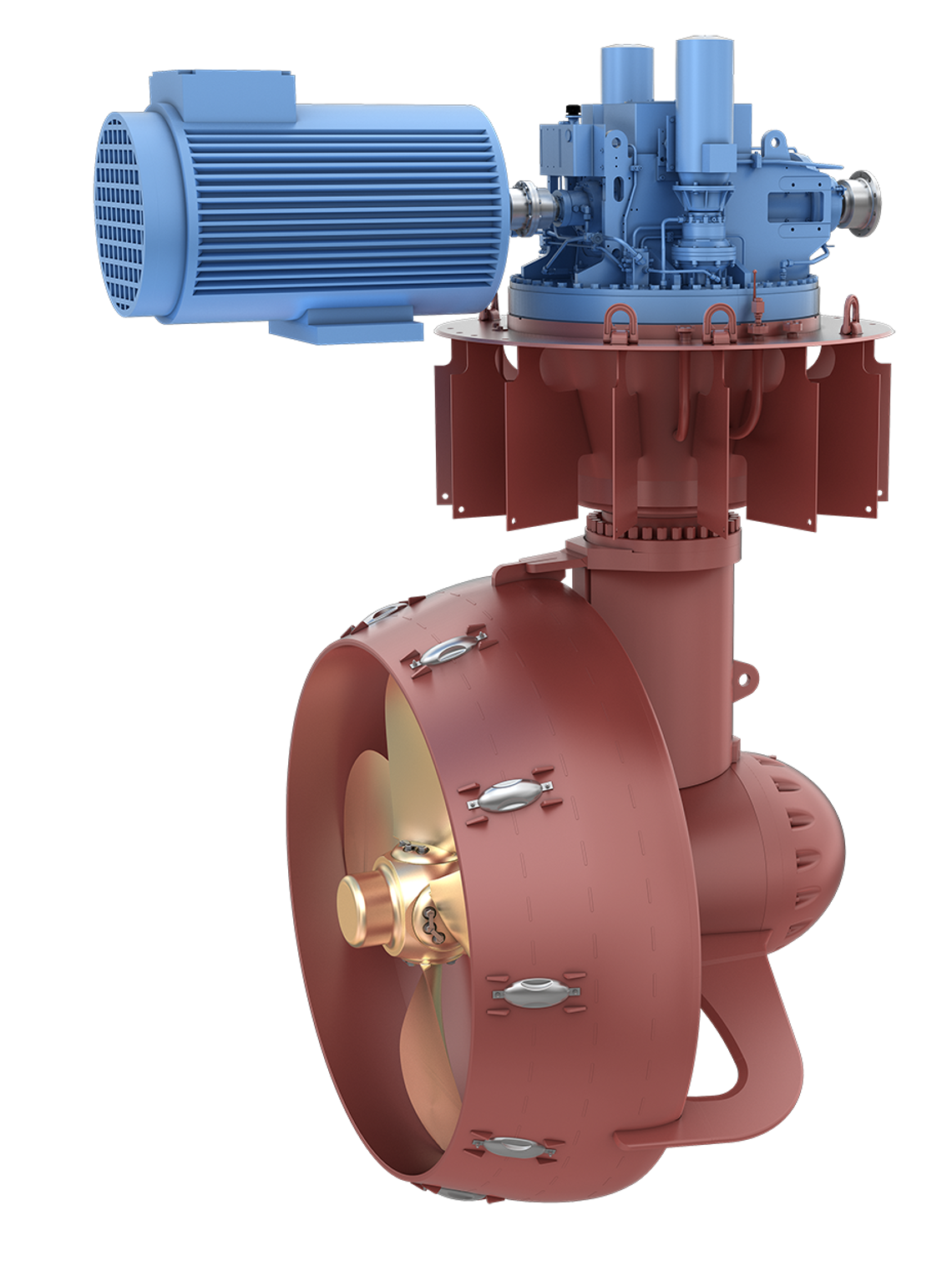

US Azimuth Thruster

US TYPE AZIMUTHING THRUSTER

KONGSBERG US thruster family has set the industry standards for decades being one of our all-time most selling propulsion product, generating real value for our customers with products and integrated solutions tailored to your individual needs.

US thrusters have been the obvious choice for ship applications where reliability and performance really matter, which is proven by over 7000 globally delivered US units in the past 50+ years. Success story continues with new generation azimuth thrusters which are compatible with hybrid and electric solutions.

THRUSTERS DEVELOPED TOGETHER WITH OUR CUSTOMERS

Towing industry is one of the main market segments for US thrusters. Many tug owners today are more and more interested in the product life cycle costs than the lowest purchase price. Effective shipyards are searching ways to cut both time and costs from boat building processes. The shipping industry sets new standards for performance to be able to tow larger vessels. We have been listening to our customers and created new features accordingly, many of them being a win-win solution for all parties.

US PM improved L-drive design

The US PM has a new improved L-drive design which means it is lower in height and has been especially designed to meet Tug design and yard requirements. The improved US PM thruster design is a direct response to the modern ship designs like tugs, which require a compact unit due to less space in the thruster room. The new US PM L-drive design will be available in the most common sizes for tugs. The bollard bull can be enhanced even more by using one of our most recent nozzle designs, the PRO-DUCT nozzle.

Our PRO-DUCT nozzle design was developed to further enhance the efficient bollard pull concept for US thrusters on tug applications, suitable for working in the most demanding conditions with up to 3,5% increase in bollard pull performance, compared to current Kongsberg design TK nozzle and propeller.

Flexible modular design, options to choose from

- Drive: Hybrid- twin, Hybrid-dual, mechanic and electric

- Clutch: On/off-, Low dissipation slipping- and High dissipation slipping clutch

- Steering: Hydraulic and electric steering

- Mounting: Several different Weld-in and Bolt-in options

- Various sealing options based on application requirements

- Propeller: CRP, FP and CP with multiple different nozzle sizes

Future proof digital features:

- Condition based monitoring system

- Digital twin system for predictive maintenance

- Remote access and diagnostics for control system

- Remote and autonomous operation compatibility

- Integrated control system for thruster and deck machinery

US PM L-Drive thruster

US255 with Pro-Duct

US with dual input, Hybrid

US Thruster twin input

Superior Thrust Performance

- Unique propeller and nozzle combinations to enable highest efficiency at design point

- Inhouse HRC hydrodynamic research center with cavitation tunnels for

- R&D and customer projects.

- Project specific CFD modelling capabilities

Value adding services:

- Extended thruster coverage

- Fixed price overhaul solution

- Online / offline Condition monitoring services

- Thruster exchange pool

- Energy management system

- Global service coverage

TECHNICAL DATA

| US Thruster Type |

Propeller Dia. Ducted [mm] |

Max. power. [kW] |

Bollard Pull [mtons] with 2 x AZM, max Power |

| 55 | 1050 | 350 | 11 |

| 105P6 | 1300 | 500 | 17 |

| 105P9 | 1500 | 750 | 24 |

| 1600 | 750 | 25 | |

| 155P12 | 1600 | 900 | 29 |

| 1800 | 1100 | 35 | |

| 155P14 | 1800 | 1150 | 37 |

| 2000 | 1370 | 45 | |

| 165 | 2200 | 1471 | 50 |

| 2400 | 1340 | 50 | |

| 205 | 2300 | 1870 | 60 |

| 2400 | 2000 | 65 | |

| 2500 | 2000 | 67 | |

| 2800 | 2000 | 70 | |

| 255 | 2600 | 2390 | 77 |

| 2700 | 2560 | 81 | |

| 2800 | 2560 | 85 | |

| 3000 | 2600 | 91 | |

| 35 | 2800 | 2790 | 91 |

| 3000 | 2900 | 97 | |

| 305 | 3000 | 3200 | 104 |

| 3200 | 3300 | 111 | |

| 355 | 3200 | 3600 | 117 |

| 3500 | 4050 | 135 | |

| 60 | 3800 | 5500 | 174 |

| 4000 | 5500 | 180 |

Lifecycle support for your vessel

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

Upgrading and enhancing your vessel’s performance.

-

Training

Maximise crew efficiency and reduce downtime with expert training.