The pioneer trail

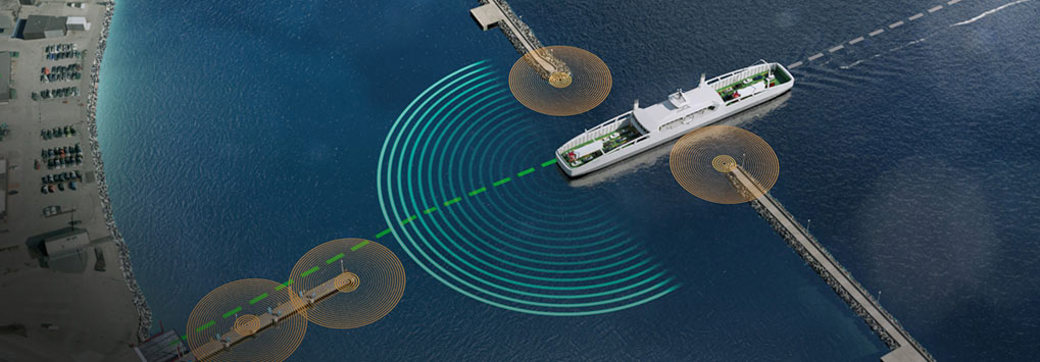

Our first Autocrossing system for ferries is now in operation. Fjord1’s full-electric double-ended car ferry Gloppefjord now uses Autocrossing on the short Anda - Lote link on the E39 highway in western Norway. A sister ship, Eidesfjord, has also joined the pioneer on the same route, exploiting technology that simplifies the ferry crossing and significantly cuts energy consumption.

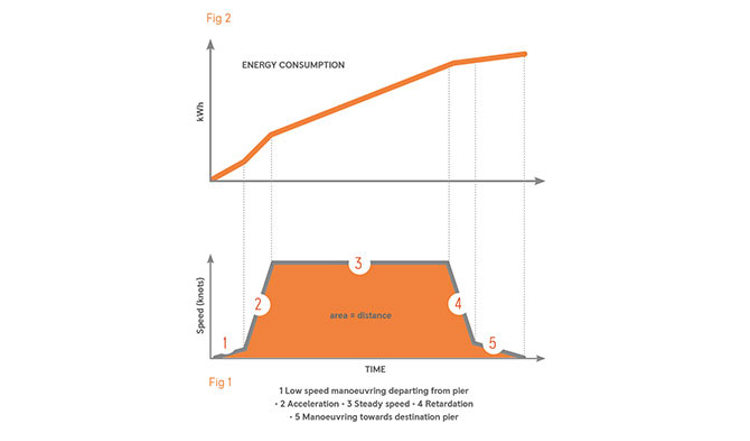

A ferry crossing involves automating a distinct series of operations: departure from the linkspan, acceleration to transit speed, transit at constant speed, deceleration on approach to the terminal, and manoeuvring before connecting to linkspan.

Part way to autonomous

At present, our Autocrossing system is configured to cover the middle three elements, leaving the docking manoeuvring to the captain.

Shortly after leaving the dock, at a designated point the operator can engage the Autocrossing system. At the other end, in the predetermined arrival zone, the captain disengages the system and takes manual control for the docking manoeuvres.

If they are incapacitated or forget, the system brings the ferry to a safe stop in the arrival zone, keeping it automatically in a fixed position instead of continuing into the terminal. The captain can also disengage the system and resume command any time during crossing.

Acceleration, transit and deceleration are the phases where most of the energy is consumed in ferries of this type. Autocrossing optimises this for different vessel loads and weather conditions while keeping to agreed departure times and crossing durations. Drawing on the extensive experience and know-how of our hydrodynamics team, advanced optimisation methods have been developed to ensure the highest possible energy efficiency.

Propulsion motors are the largest energy consumers, so savings come from providing only enough power to smoothly accelerate the ferry to the required cruising speed in the available time. Leaving this to the Autocrossing system also takes away variations in manual operation.

The Autocrossing continuously optimises the relationship between propeller pitch and rotational speed, the use of steering angle and power distribution between aft and forward thruster(s).

“Our Autocrossing system simplifies the ferry crossing operation and cuts the energy consumption per trip to the minimum,” explained Jann Peter Strand, Product Manager for Automation and Control.

“At the same time it documents both performance and energy consumption, and also helps to improve operating safety. The system is delivered as an integrated solution with propellers and control systems from Kongsberg Maritime, both for newbuilds and retrofit projects.”

Gloppefjord and Eidesfjord were designed by Multi Maritime, who worked with us to ensure the Azipull thruster propulsion system and hullform work together to cut the energy requirement to a minimum and to ensure sufficient low-speed thrust or manoeuvring power during adverse weather conditions, reducing the battery size needed.

The battery-only vessels replace diesel-powered ferries, and the lithium ion batteries are charged from shore connections to the local power grid at each terminal.

Azipull AZP 85CP-F thrusters are located one at each end of a ferry. Both will be powered when manoeuvring and accelerating away. In transit, power is proportioned between the fore and aft thrusters to give the highest propulsive efficiency.