In Trondheim, 3D printing has become an important tool for the research and development department at Kongsberg Maritime.

-

Text:OVE RONNY HARALDSEN

-

Ove Ronny HaraldsenGroup Communication Manager

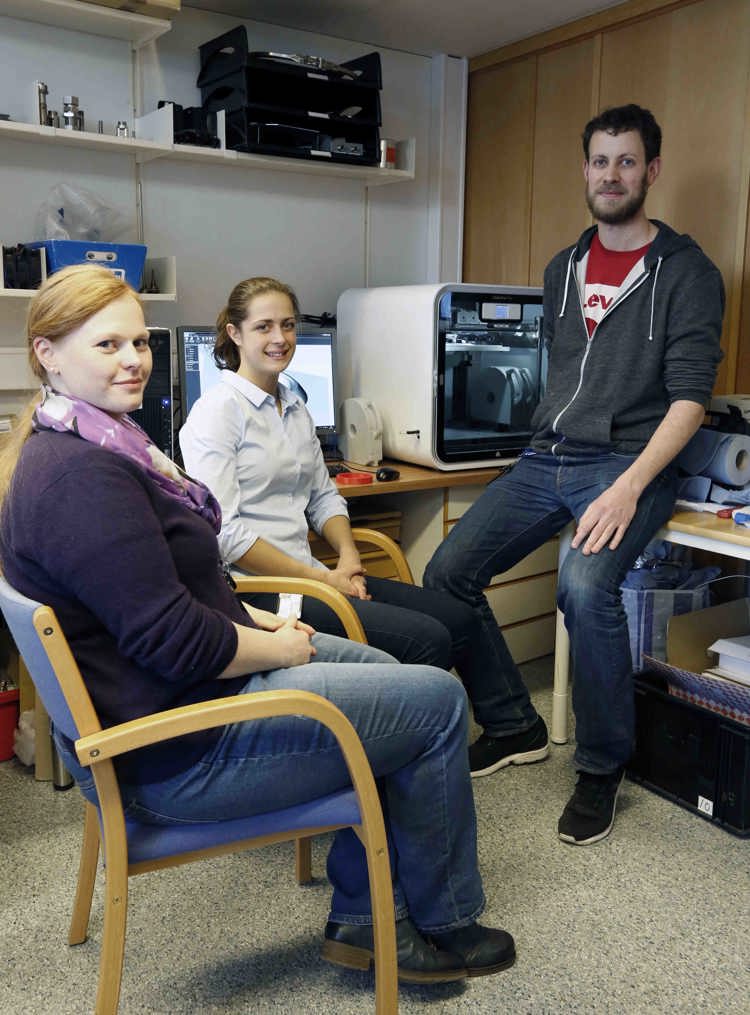

In a corner of the Kongsberg Maritime laboratory at Lade, there it is: Walter the 3D printer. It’s hard at work printing out yet another prototype for a vibration monitor for wind turbines. The sound is reminiscent of an old-fashioned inkjet printer for paper, but this one doesn’t use ink – what comes out of the nozzle is melted plastic.

Layer by layer, the plastic forms the exact shape that Maria Nissrin Foshaug and her colleagues have designed using computer-aided design technology. This relatively simple 3D printer arrived here about one year ago, and since then has become the first step into a new world for the developers at Lade.

“The 3D printer we now have is more or less a learning tool that will enable us to use bigger machines later. You don’t buy a million dollar printer without some kind of experience. This is teaching us how the printer builds things up in layers, which helps us to understand how we have to design things”, says Maria Nissrin Foshaug.

FANTASTIC OPPORTUNITIES

3D printing is expected to create a revolution in the way things are produced. Traditionally, people have cut in stone, cast in iron, carved in timber and milled in titanium. Now shapes can be constructed from scratch, and this is only the start. Interest in 3D printing has been increasing radically over recent years, particularly once the most important patents to the technology expired. The machines do not only print in plastic, but also in metal, cellulose and ceramic.

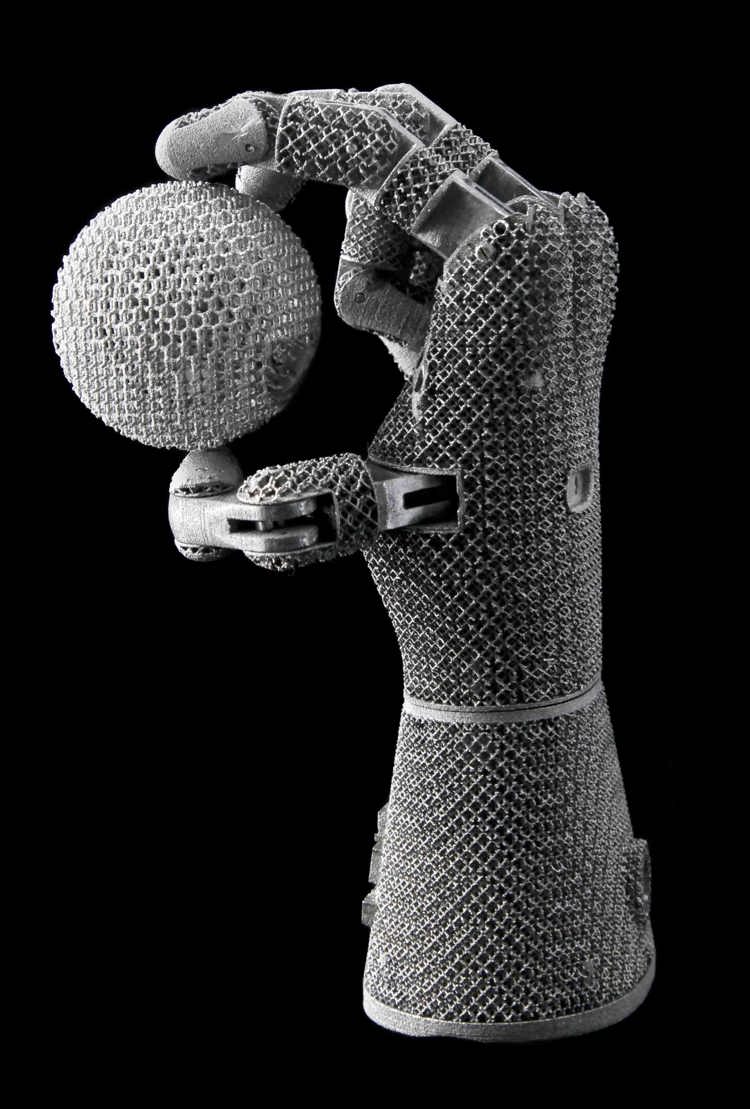

The biggest advantage of 3D printing is its ability to create shapes that cannot be machined using traditional methods. For example, the fuselage of a drone is made up of a strong but light internal support structure that is far beyond anything we can achieve in composites today. Fantastic mechanics, moving parts and electronics inside closed structures. For the engineer, 3D printing is a unique opportunity for new shapes, functions and innovation.

“MUST BE JUSTIFIED”

In Trondheim the developers are meeting to discuss the latest version of the vibration monitor they are developing in partnership with The Research Council of Norway, SINTEF and NTE. Together, they review the model they have just printed out. They pick it up, feel the shape, stick on a little plasticine, discuss. Previous generations of the model are also on the table. Ideas that were either discarded or developed with modifications. Audun Lønmo Knudsrød is running the project.

“Our understanding of what we are designing is hugely helped by the fact that we can see it in a materialised form. After we got the 3D printer, our development work has gone much faster”, explains Knudsrød.

Up to now, the development team in Trondheim have been designing components they know can be machined using traditional methods.

“If we design geometrical shapes that we cannot machine, we will have to use 3D printing for mass production. However, 3D printing is expensive and will make the products more expensive for the customer. So from this point of view, we have to justify the use of 3D printing by demonstrating its unique properties”, explains Knudsrød.

TECHNOLOGY IS STILL IMMATURE

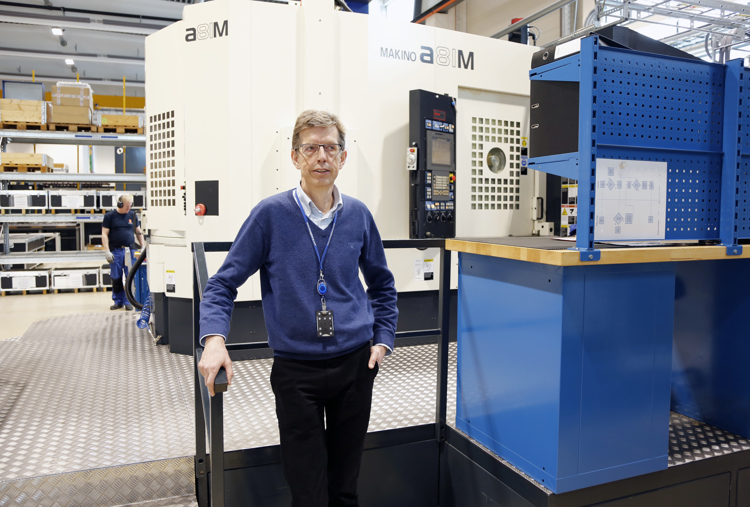

Since the autumn of 2014, Alf Pettersen, Technical Manager at Kongsberg Aerostructures, has been making a thorough study of the technologies that are currently available in 3D printing. Conferences, meetings with suppliers and visits to reference installations have given Pettersen an excellent insight into how far the technology has come. His conclusion is that 3D printing is still an immature technology, particularly in the field of metals.

“3D printing has come a long way in terms of medical devices and prototypes, but mass production is still a problem. This is because of challenges relating to repetition and quality. It is not good enough in so many areas, particularly in the aviation industry where there are extremely strict requirements governing quality and the qualification of methods”, says Pettersen, while emphasising that there are exceptions.

“General Electric has developed a completely new nozzle for injecting fuel into their new LEAP aircraft engine. Their designers have achieved a completely new type of function by using this technology” explains Pettersen.

“So the strength of 3D printing is in the functions of the finished components”?

“Absolutely. Design and production are very closely linked. 3D printing allows us to design products that up to now we have not been able to manufacture. As the technology gradually becomes more mature, the opportunities will begin to become more apparent. Then we will start to see ideas for products and components with properties that are completely different to those we are used to today”, says Pettersen.

KONGSBERG’S NEXT MOVE?

KONGSBERG has now put together a working group led by Alf Pettersen, who will be looking into the approach to 3D printing from a group perspective. The Kongsberg Technology Forum is taking the initiative; this forum is led by technical managers across the entire group. The working group will examine potential partners, and the status and needs of KONGSBERG, and will come up with a recommendation as to what the group’s next move should be.

“3D printing is an area in which KONGSBERG needs to have a uniform approach. One industrial 3D printer costs several million kroner. If we decide to make this kind of investment, we will have to ensure that every part of the company gets an opportunity to learn the technology. It’s too early to reach a conclusion, but the obvious place for a 3D printing competence centre for the entire KONGSBERG group is the composite factory at the Arsenal”, says Pettersen.

“When do you think that the technology will be mature enough for 3D printing to become a real alternative in mass producing metal components”?

“I would estimate that within three to five years, mass production with 3D printing will have become more common. But I must emphasise that I am talking on a general basis, not in relation to production here at the Arsenal”.

ELITE INDUSTRIAL CENTRE

There are currently only four industrial metal printers in Norway. One is at the Norwegian University of Science and Technology (NTNU) in Trondheim, and the other at Gjøvik University College. The other two are privately owned by the companies Tronrud Engineering and Promet. Many companies are still sitting on the fence, waiting for the technology to become mature enough to bring payback from investments.

An “elite industrial centre” along the same lines as the Elite Sports Centre is an idea that has been launched by KONGSBERG, with the aim of bringing together the best digital teams in Norway to share ideas, perform testing and learn from each other. Physical test facilities including industrial metal printers could be part of the investment in an elite industrial centre. It could speed up innovation that is hampered by costly investment expenses.

“Our thinking is that this kind of elite industrial centre would help to improve the digital skill level of our many hundreds of subcontractors and other Norwegian industrial companies”, says CEO Walter Qvam.

The aim is that with access to world class industrial innovation centres, Norway can continue to be the best in innovation in key industrial areas.

GETTING IN EARLY

In Trondheim, the idea of an elite industrial centre has been met with enthusiasm. Maria Nissrin Foshaug and Audun Lønmo Knudsrød are itching to step up from Walter the plastic printer – to printers that melt metal powder using lasers.

“Developments are really fast. For a smaller company, it would be extremely expensive to buy a printer that will be out of date in a few years and cannot be used commercially. However, if you had access to printers at an elite industrial centre, you could go there and try out the opportunities provided by the various kinds of printers”, says Knutsrød.

“It’s important to get involved in the development of 3D printers at an early stage. That way you learn how these kinds of printers work, what they can do and what they cannot do. It takes a long time to learn how to design for 3D printing and manufacturing. The investment in skills is as big as the investment in machines. That’s why it’s important to get in early, so that you have the skills that you need when the technology is mature and 3D printing really gets going”, concludes Maria Nissrin Foshaug.